PRECISION GRINDING TECHNOLOGY

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

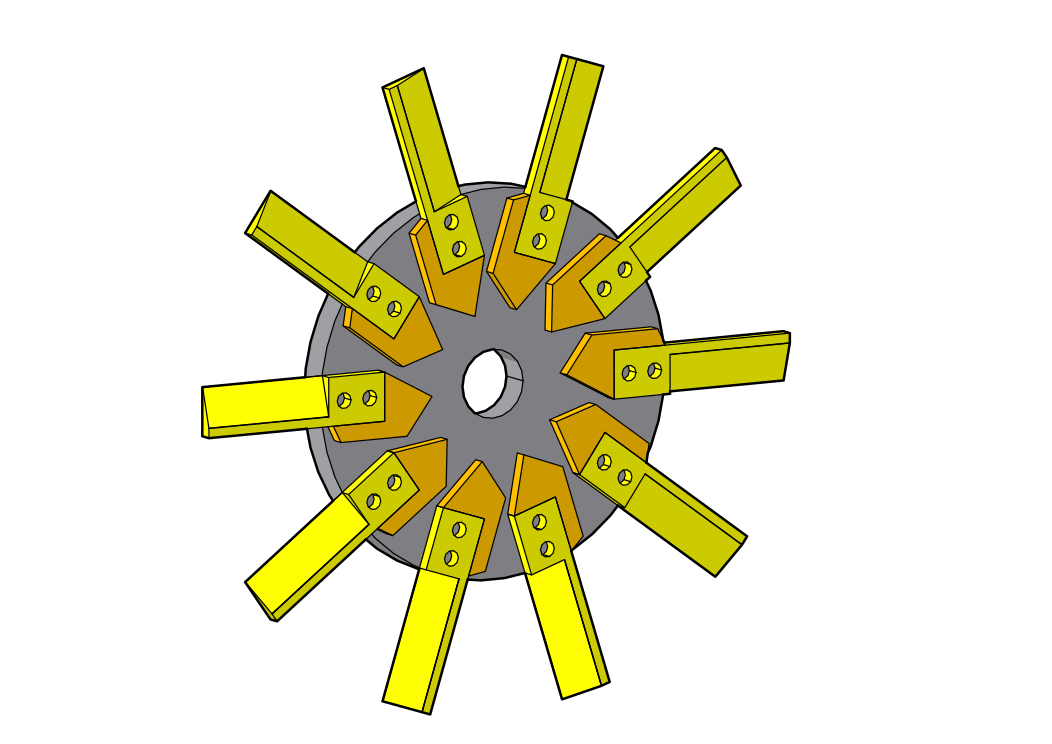

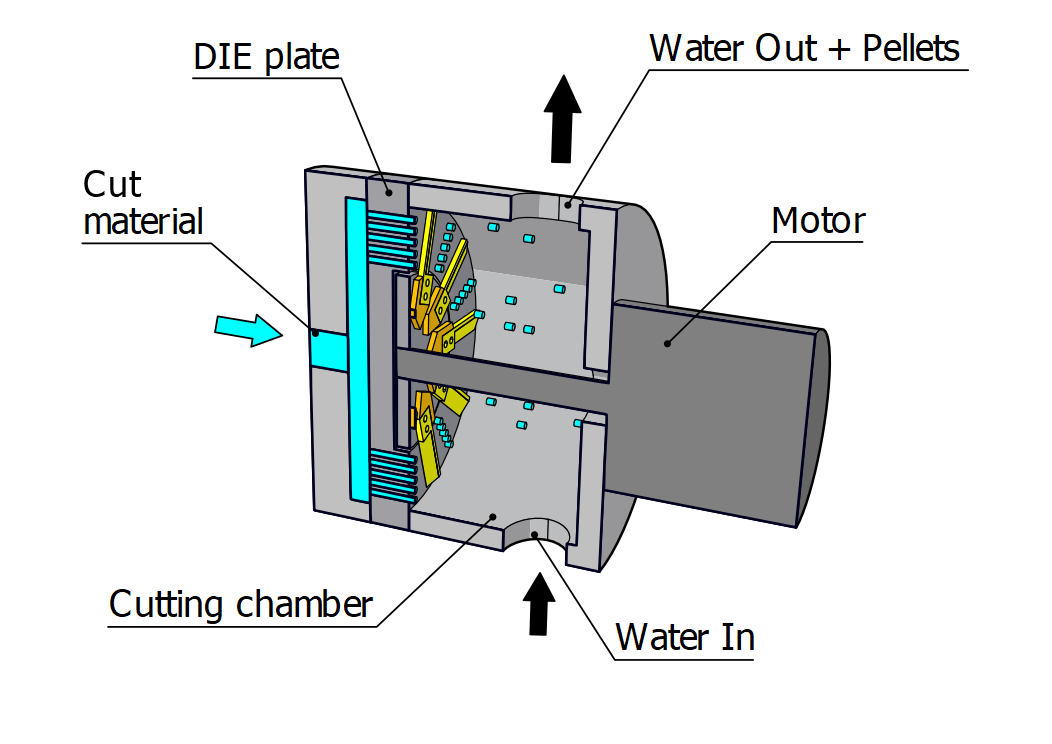

Pelletizer knives cut plastic or other materials into small, uniform pieces known as pellets. It can be used in various industries, including plastics, rubber, and chemical processing. They are used to produce animal feed and recycle materials such as plastics and rubber pellets.

The bodies of pelletizer knives are usually made of high-carbon stainless steel. The cutting edge is typically made of a bi-material such as Nikro-128 due to the high wear resistance needed during the cutting process.

Pelletizer knives or pelletizer blades are used for pelletizing operations. For better quality, the body of pelletizer blades is usually made from high carbon stainless steels, while the cutting is manufactured from bi-metal materials such as Nikro-128 due to the required high wear resistance during the cutting operation.

Besides manufacturing custom size pelletizer knives and pelletizing blades, Baucor stocks a wide array of OEM knives for pelletizer brands including AST, Berringer, Berstorff, Black Clawson, Buss Condux, Conair, Cumberland, Egan, Erema, Farrell, Gala, Ikegai, JSW, Kobe, PTI, Rieter/Automatik, Werner Pfleiderer and many others.

Our pelletizer knives are manufactured to meet the exact specs and tolerances of OEMs. If precision, quality and short lead time all matter, then you are at the right place. Baucor manufactures and supplies literally tens of thousands of pelletizer knives and blades. Whether you need your pelletizer blades in standard sizes or custom dimensions, Baucor can turn your desing into a blade in just days. Regardless of what brand your pelletizer knives, our pelletizer blades are exceptionally made from quality ground hardened tool steels and stainless steel as well as Tungsten Carbide and Carbide-tipped upon our customers' request.

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

BAUCOR® is highly specialized in manufacturing custom industrial blades. If you need your knives manufactured to your exact requirements, please contact us now.

With underwater pelletizer blades made by Baucor, we guarantee that your application will run smoother and longer.

Please contact us today filling out our online form here to ask about specific size and models and an extensive list of standard in-stock industrial blades and machine knives. If you have a drawing, sample or your desired specifications for a custom blade you need manufactured, please send them using our our online form here.

BAUCOR® has three main offices located in California - USA, London - United Kingdom, and Mannheim - Germany to reach and serve our customers globally. We design, engineer, and produce precision industrial blades, machine knives, custom tools manufactured to exact specifications.

We also supply thousands of in-stock BAUCOR® industrial blades and machine knives from these locations.

Contact our experienced sales engineers in one of our offices conveniently located in California, UK, and Germany to discuss your needs.

We are highly specialized in manufacturing custom pelletizer knives and blades per sample and drawing. If you need your knives manufactured to your exact requirements, please contact us now to see how we can make high quality pelletizer knives exceeding your requirements at a competitive price and always delivered right on time.

Small or large, BAUCOR® manufactures all types and shapes of precision circular blades in nearly all materials available in the market.

Whether it is 5mm or 2500mm long, BAUCOR® has the right capacity and advanced capabilities to manufacture precision industrial blades.

Did you know that BAUCOR® has manufactured tens of thousands of precision punch blades? Get your quote today!

Manufacturing custom industrial blades is no easy task that anyone can handle. That's why BAUCOR® is here to help!

There are many advantages of using pelletizer knives:

BAUCOR® manufactures razor and straight blades as small as 5mm and as large as 2500mm.

Punch blades must be made to exact specs. Turn to BAUCOR® just like thousands of customers around the world.

Whether you need circular slitter blades or flat slitter blades, BAUCOR® is here to turn your design into precision part.

BAUCOR® manufactures precision top quality toothed blades in all shapes and form.

Need to make a slit or cut through your material as precise as possible? BAUCOR® pointed blades are of highest quality in the market.

Top and bottom shear and slitter blades from BAUCOR®.

American or European style! BAUCOR® has the correct holder for you!