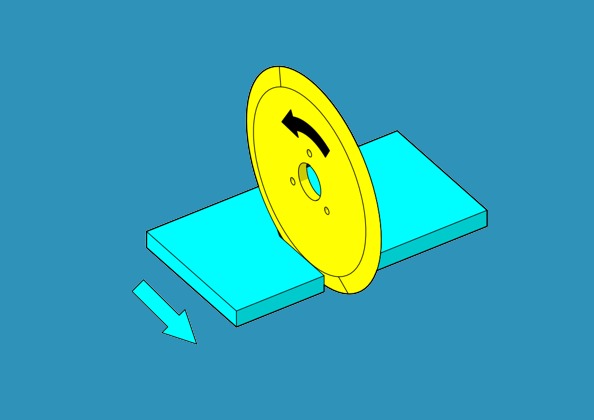

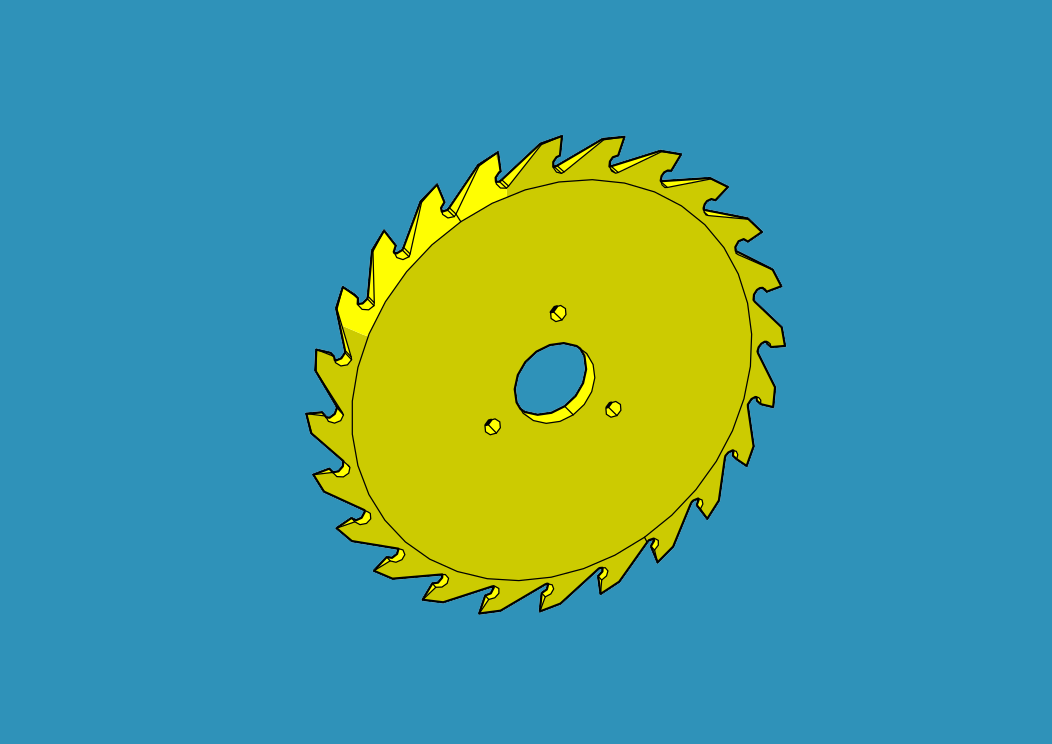

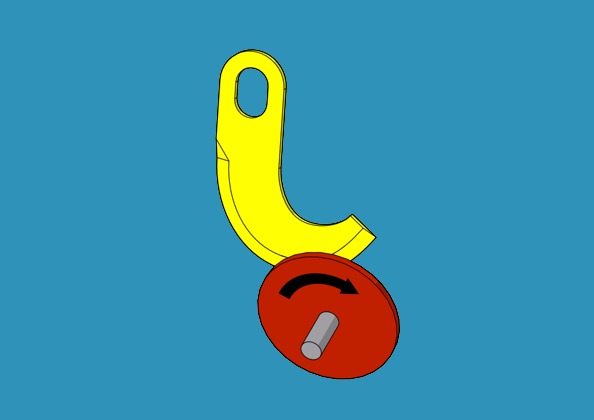

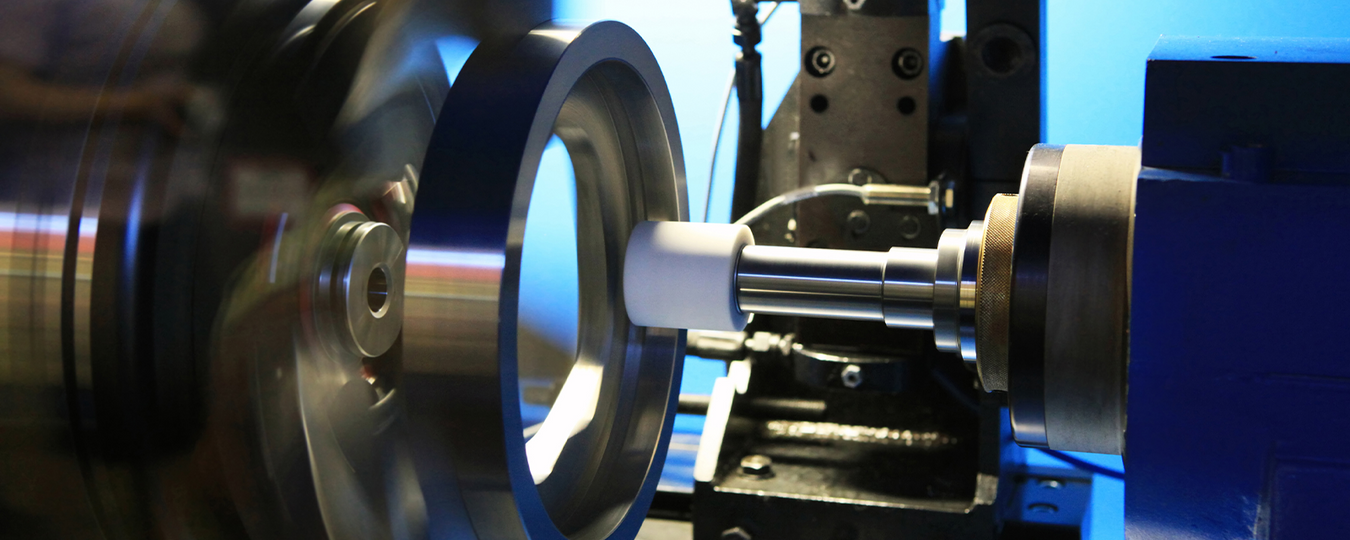

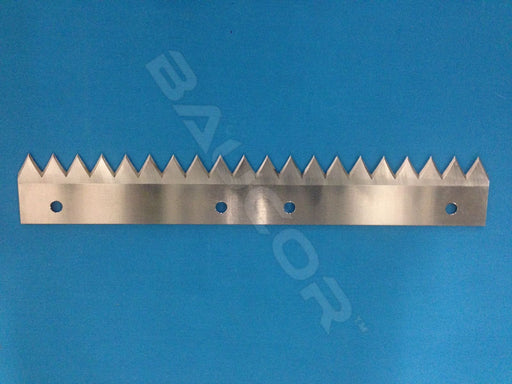

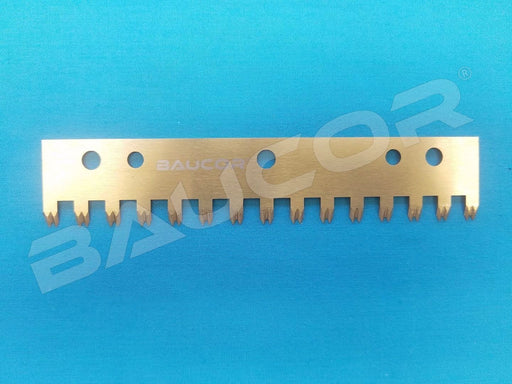

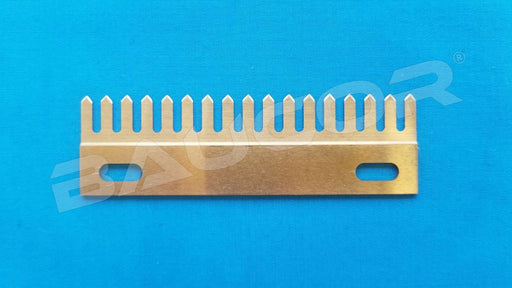

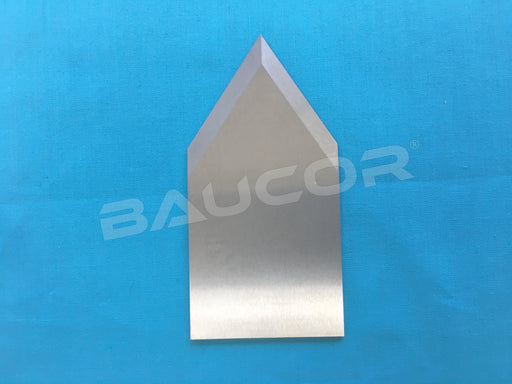

Food processing knives are specialized tools used in food processing and preparation applications. These knives are designed to handle various tasks, including cutting, chopping, slicing, dicing, and peeling different types of food.

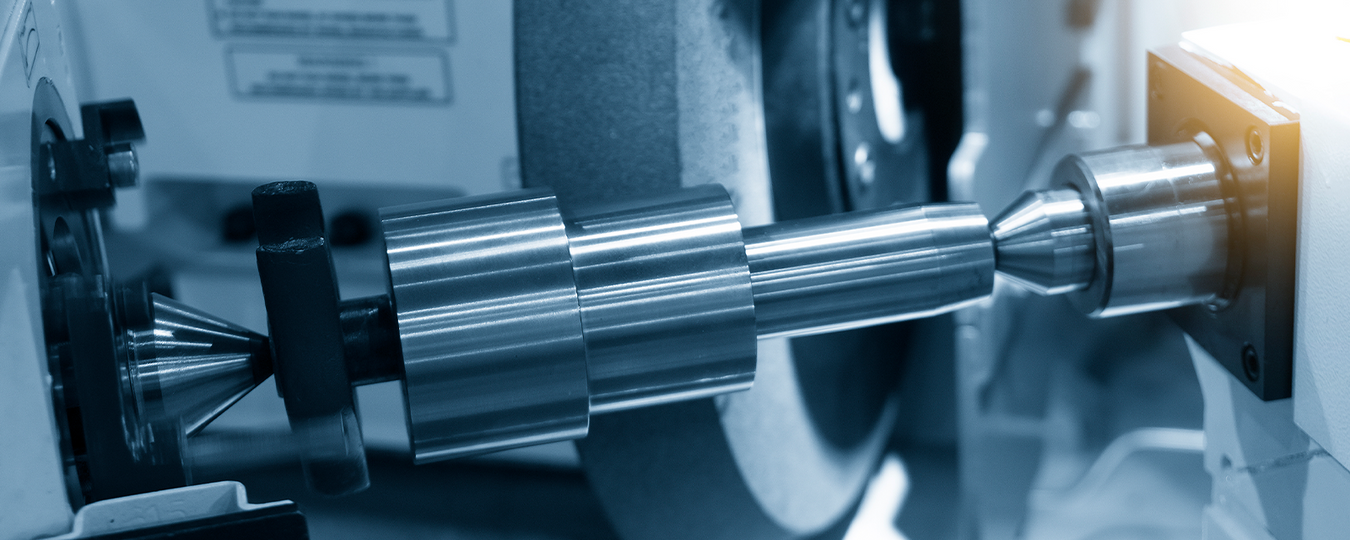

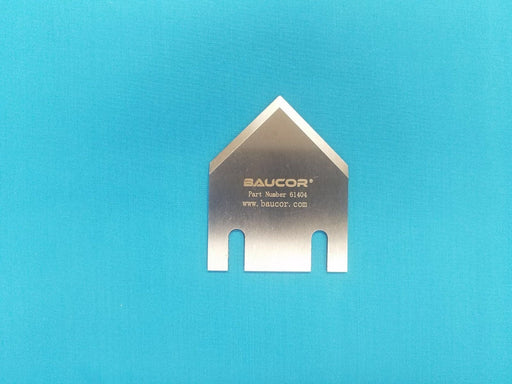

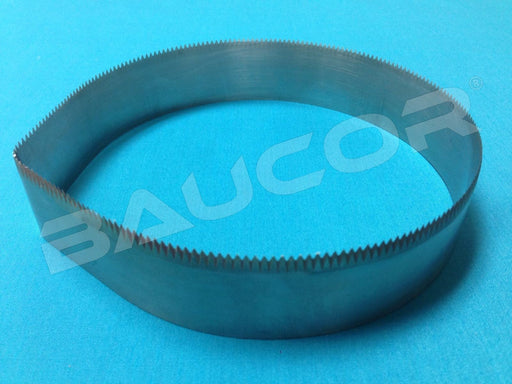

Food processing knives are made from high-quality, durable materials such as stainless steel and have a variety of blade shapes and sizes suited for different tasks.

Food processing blades or as some call food processing knives are used for cutting operations such as chopping, slicing, dicing, peeling. Selecting the correct stainless steel type for food cutting operation is extremely important in food processing due to the acidic nature of food leading to faster wear of the steel, and potentially leading to contamination of the food with the oxidation build-up on the blade surface.

English

English