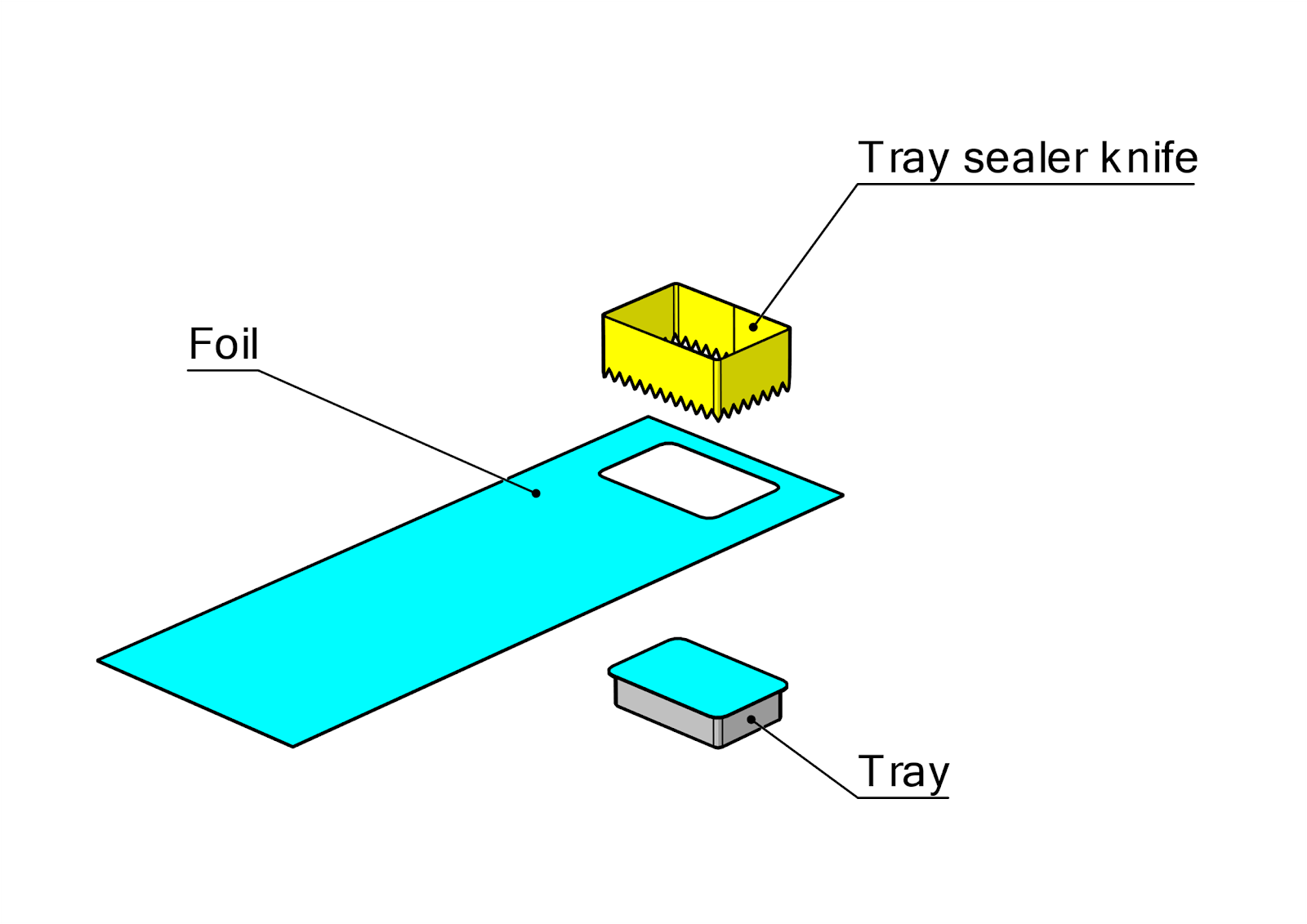

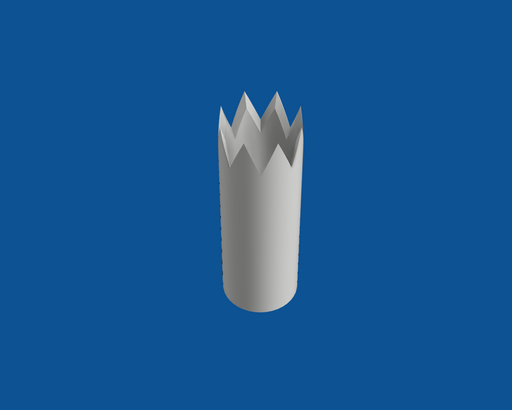

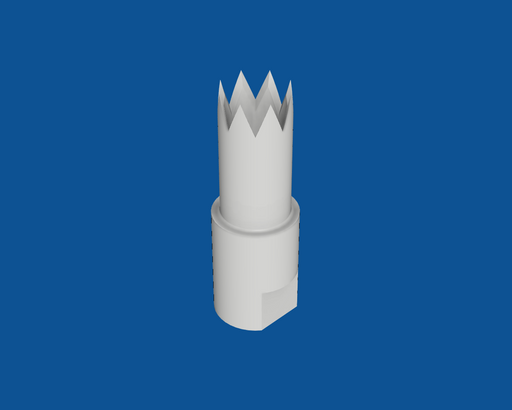

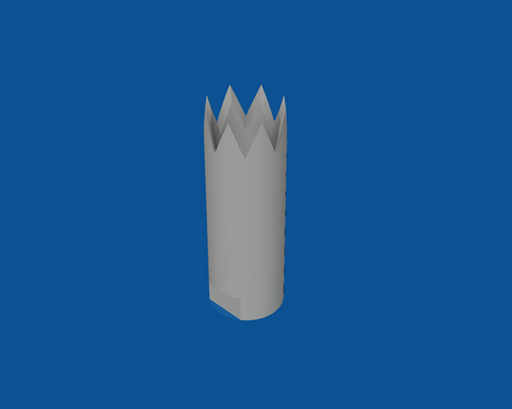

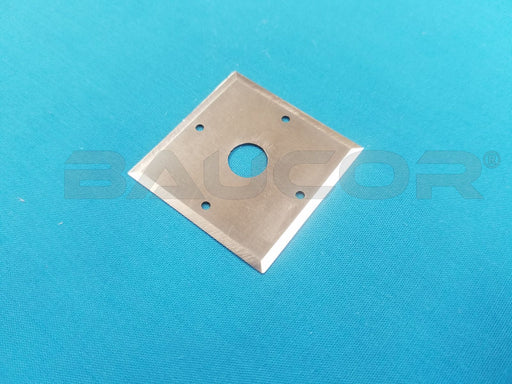

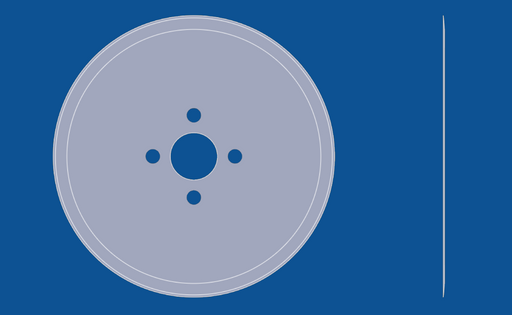

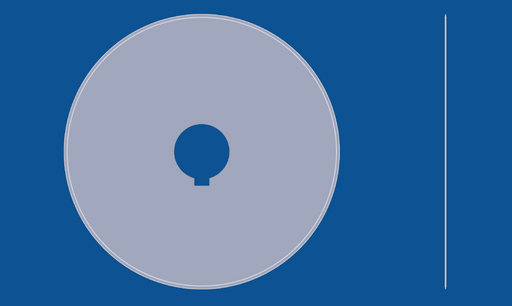

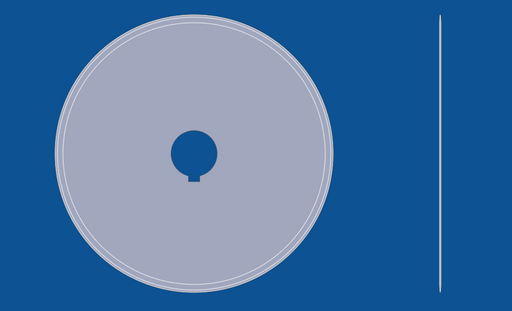

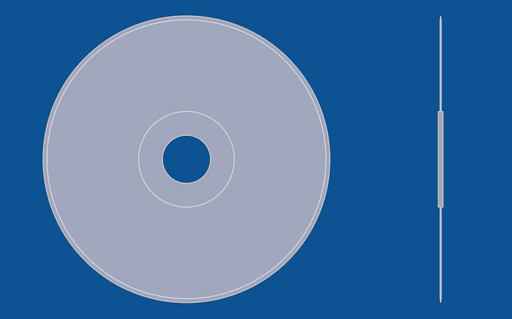

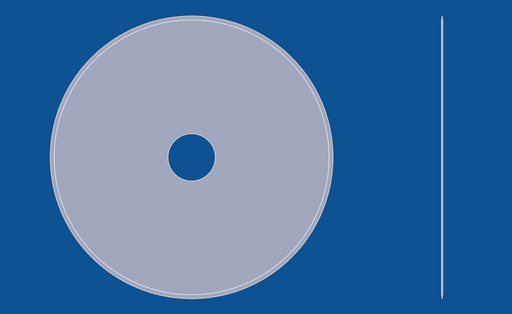

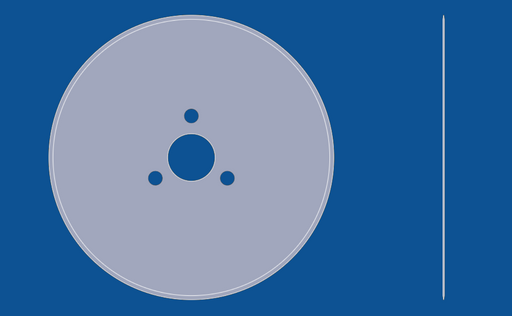

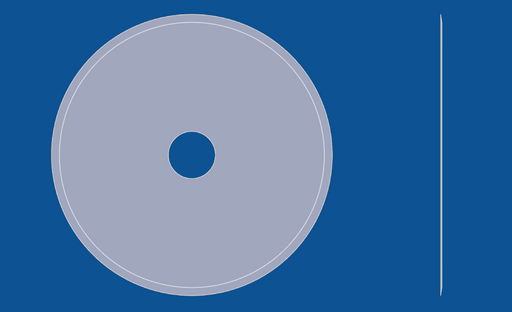

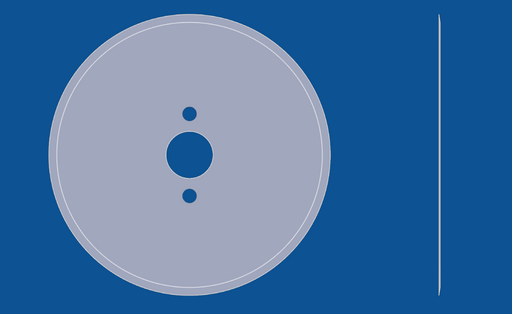

Tray sealer knives are tools used to seal trays or containers with a lid or film. They are typically used in the food industry to package meat, poultry, seafood, fruits, vegetables, and prepared meals. Tray sealer knives are used in conjunction with tray sealing machines, which are automated machines that use heat and pressure to seal the trays.

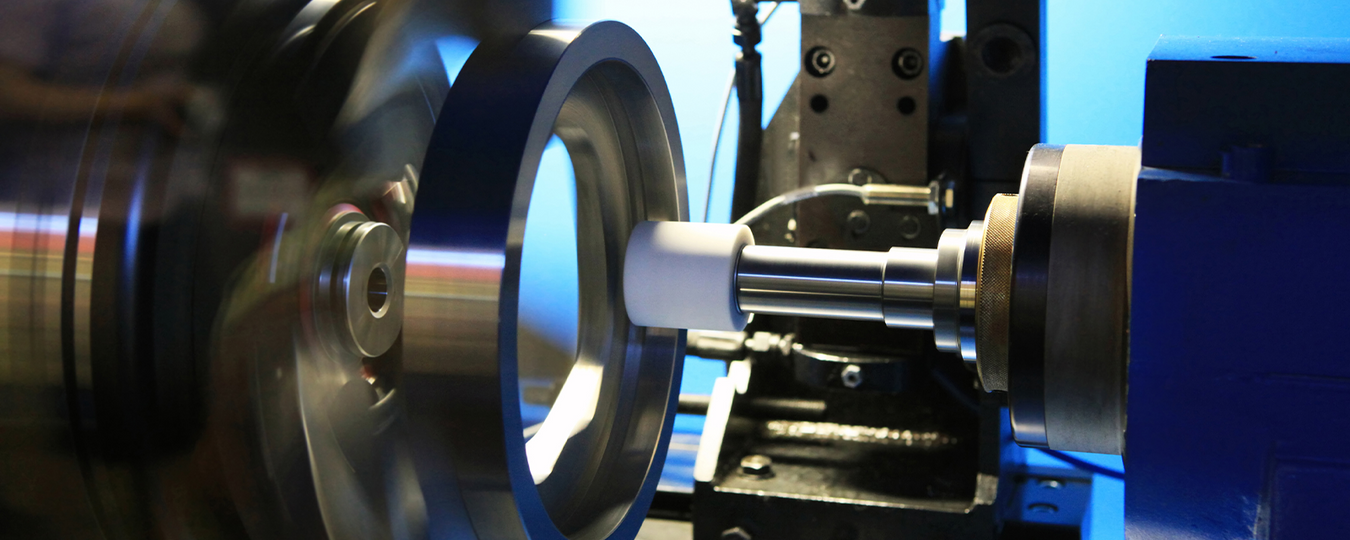

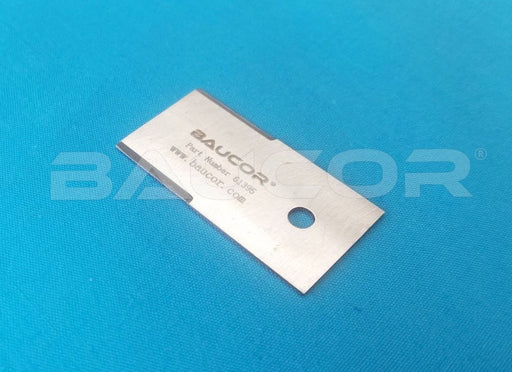

Tray sealer knives are typically made of high-quality stainless steel or other durable materials to withstand the high temperatures and pressures involved in sealing. They are designed to be sharp and precise to ensure a tight, secure seal on the tray or container.

Baucor manufactures all shapes and kinds of tray sealer knives and tray sealing blades used in packaging, food, paper, plastic film applications. We manufacture and supply both standard and custom size precision tray sealer knives for all kinds of industries. Whether you need custom or standard off-the shelf tray sealer knives, Baucor can turn your design into a blade in just days.

English

English