Custom Solutions for Industries: BAUCOR in Machine Knife Manufacturing

Custom machine knife manufacturing is crucial in various industries, including packaging, food, plastic, tires, and rubber. These specialized knives ensure efficiency and precision in cutting materials to meet specific requirements. Whether slicing through tough rubber or precise cutting in the food industry, custom machine knives are indispensable tools that cater to diverse needs.

In the competitive landscape of modern manufacturing, having access to high-quality custom machine knives can make all the difference. Companies rely on these precision tools to consistently enhance their production processes and deliver top-notch products. It is where BAUCOR comes into play with its expertise in designing and producing customized machine knives tailored to clients' unique specifications.

With years of experience and a commitment to excellence, BAUCOR is a trusted partner for businesses looking to optimize their operations with reliable cutting solutions. By leveraging advanced technology and innovative techniques, BAUCOR continues to set industry standards for quality and performance in custom machine knife manufacturing.

Invest in custom machine knife manufacturing with BAUCOR today for cutting-edge solutions that drive success in your industry.

Importance of Customization in Manufacturing

Customization is essential in the manufacturing sector to fulfill industry-specific requirements. Customization enables businesses to manufacture goods according to precise requirements, guaranteeing maximum effectiveness and performance.

Manufacturers can handle specific issues in several industries, including food, plastic, rubber, tires, and packaging, by designing specialized machine knives. These specialized solutions improve the accuracy and productivity of production processes.

Customization helps companies stay ahead of the curve by providing tailored solutions that address changing consumer needs. It encourages creativity and inventiveness in the development of cutting-edge solutions for a range of applications.

Moreover, customized machine knives help save money by reducing waste and downtime. Custom tools created to meet their unique needs provide businesses with enhanced quality control and lower maintenance expenses.

Customization drives technological improvements and improves overall operational performance for a variety of industries, which in turn propels progress in manufacturing.

Packaging Industry and its Need for Custom Machine Knives

The packing industry is a fast-paced field that requires accuracy and productivity. Custom machine knives are vital in guaranteeing the efficient running of packaging operations. These specialist instruments are made to satisfy the particular needs of various packing materials, such as cardboard, paper, plastic, and metal.

Manufacturers may accomplish precise, clean cuts with custom machine knives, improving the appearance and quality of their products. These blades' capacity to be customized to meet precise measurements and forms guarantees uniformity in the cutting processes, lowering waste and boosting output.

Custom machine knives provide unmatched performance in sectors where time is of the essence by producing quick and accurate cuts. Having blades specifically designed for each application—whether for pharmaceutical or food packaging—is crucial to achieving production goals while upholding strict quality requirements

Businesses in the packaging sector can streamline operations, cut down on downtime, and eventually gain a competitive edge in a constantly changing market by investing in custom machine knives made to fit their demands.

Food Industry and the Role of Custom Machine Knives

Efficiency and precision are critical in the food industry. Custom machine knives are essential for ensuring that food processing processes are efficient and reliable. These specialty instruments are necessary for portion control, packaging, slicing, and dicing, as well as other tasks that require precision.

Custom machine knives made for the food industry assist businesses in adhering to stringent safety and hygienic requirements. These knives guarantee consistency in size and shape, improving presentation and cutting down on waste thanks to their accurate cutting blades suited to many food product varieties.

The food industry can meet various demands with specialized machine knives in meat processing, vegetable preparation, or baking applications. Businesses can increase productivity while preserving the integrity of their products by investing in premium blades that meet particular specifications.

Custom knife manufacturing innovations have entirely changed how food makers work, enabling them to optimize workflows without sacrificing standards for quality or safety. Because of their versatility, bespoke machine knives are essential for satisfying the changing needs of the ever-changing food business.

GET A QUOTE

Plastic Industry's Dependence on Custom Machine Knives

Custom machine knives play a significant role in the plastics industry's ability to maintain accuracy and productivity during manufacturing processes. These specialist instruments are necessary for chopping, molding, and molding different kinds of plastic utilized in many different products. Custom machine knives are essential to maintaining the caliber and reliability of plastic items, ranging from packaging materials to automotive components.

Specialized machine knives used for the plastics sector must adhere to stringent specifications for performance, durability, and sharpness. Precision tools are designed to manage the distinct properties of many plastic kinds effortlessly, be it cutting through delicate polyethylene film or stiff PVC.

Custom machine knives are continually evolving to meet the ever-changing demands of the plastics sector thanks to developments in technology and materials. In the face of escalating market competition, manufacturers depend on these specialised equipment to boost productivity and maintain product quality standards.

Custom knife manufacturing innovations help plastics companies stay one step ahead of their rivals by streamlining production processes and cutting down on downtime caused by inefficient or worn-out tools.

Companies can optimize their workflow, increase productivity, and reduce maintenance and replacement expenses through collaboration with reputable manufacturers such as BAUCOR, who specialize in creating superior custom machine knives.

Tire Industry and How Custom Machine Knives Improve Efficiency

The tire industry is a challenging and intricate field that necessitates accuracy and effectiveness at every stage of the production process. Precision and uniformity in the cutting, trimming, and shaping of tires greatly depend on custom machine knives. Tyre producers can increase production and cut waste with this customized equipment that matches their specific needs.

The tire business uses custom machine blades designed to endure the demands of cutting through complex rubber compounds without sacrificing performance or quality.

These knives help manufacturers reach higher productivity levels, reducing costs and boosting profitability by streamlining cutting processes. Tire firms can expedite their production processes while upholding strict product quality standards by utilizing customized knife solutions.

Cutting-edge blade designs made especially for tire applications save downtime and increase productivity. Custom machine knives provide exact cuts that guarantee every tire component satisfies strict size, shape, and finish requirements. In the highly competitive tire market, this level of precision improves operating efficiency and adds to total product quality and customer happiness.

By increasing production speed without compromising on quality or consistency, tire manufacturers can meet market demands thanks to efficiency advantages made possible by bespoke machine knives. Bespoke knife solutions will continue to foster innovation and boost production capacities for long-term growth as the industry's technology develops.

Rubber Industry and the Versatility of Custom Machine Knives

Precision is essential in the rubber sector. The necessity for adaptable machine knives is evident, as they are needed for anything from cutting complicated designs in rubber sheets to producing custom-designed molds. Custom machine knives are essential to treat rubber more accurately and efficiently.

Rubber makers use custom machine knives to easily cut through various rubber materials' thicknesses and densities. This specialized equipment guarantees precise cuts, smooth edges, and consistent outcomes for various applications in the rubber business.

When cutting through complex rubber compounds or extracting extra material from molded products, bespoke machine knives provide flexibility and precision that regular blades cannot match. Their versatility in meeting distinct production demands renders them essential for attaining superior results in the various procedures of the rubber sector.

Custom machine knives are revolutionizing the production of rubber goods due to their exceptional cutting performance and versatility. In the ever-changing rubber industry, businesses may streamline their operations, cut down on waste, and improve the quality of their output by investing in custom-cutting solutions.

GET A QUOTE

BAUCOR's Contribution to the Custom Machine Knife Manufacturing Industry

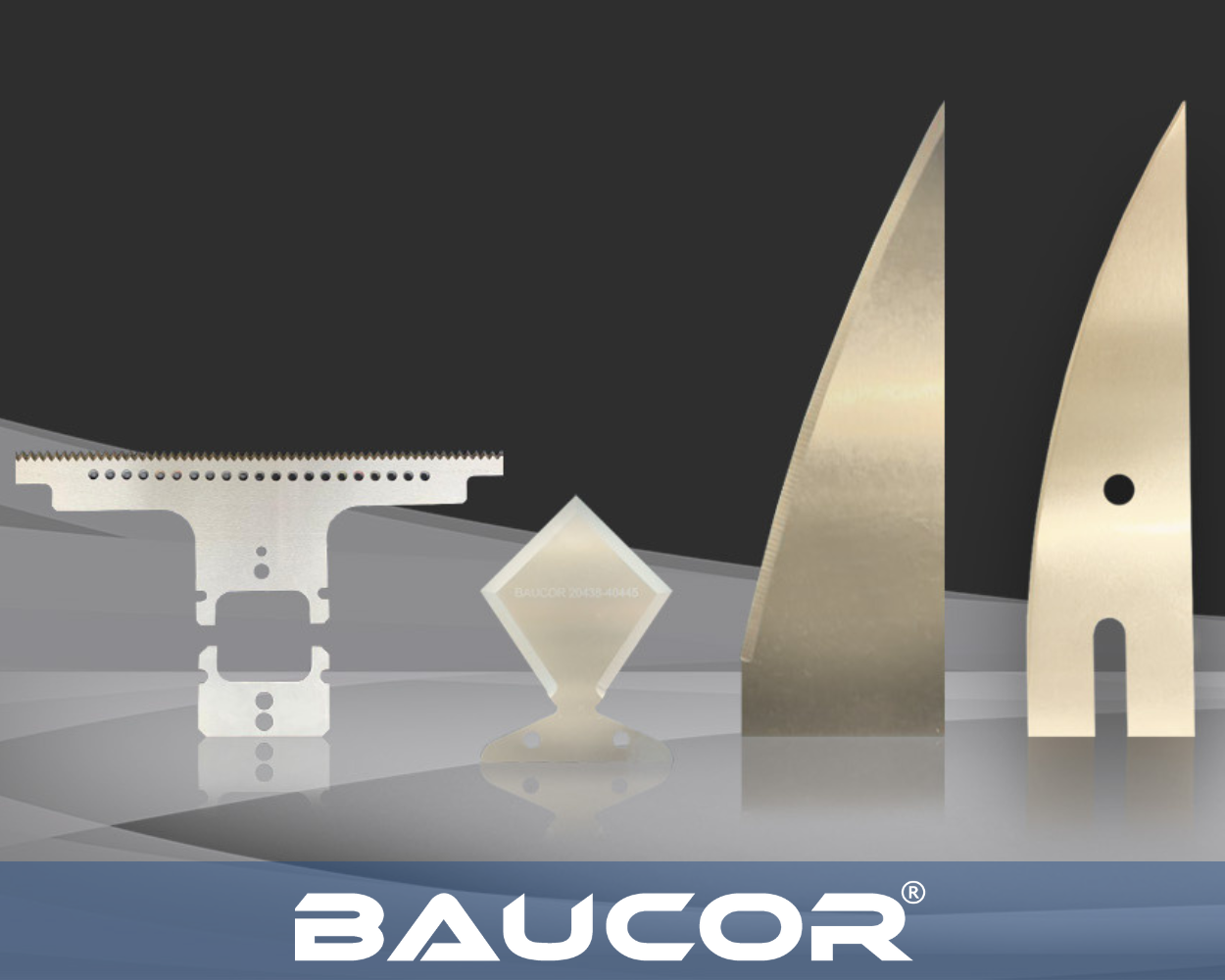

With its precise engineering and state-of-the-art technology, BAUCOR, a prominent producer of industrial blades and machine knives, has transformed the bespoke production sector. With years of experience manufacturing premium blades for various sectors, BAUCOR is distinguished by its dedication to innovation and customization.

The organization stands out in the market because of its commitment to comprehending the particular requirements of each industry, including rubber, plastic molding, food processing, packaging, and tire manufacturing. Top-notch cutting tools built for their operations are delivered to clients by BAUCOR thanks to their customized solutions that increase productivity and efficiency.

Every time BAUCOR pushes the envelope to provide unparalleled performance, it creates knives sturdy enough to cut through rigid materials like tires and rubber or intricately designed blades for packaging requirements.

Businesses looking for dependable cutting solutions catered to their particular applications can rely on them as trusted partner because of their unwavering pursuit of perfection in bespoke blade manufacture.

Conclusion

Custom machine knife manufacturing drives innovation and success across various sectors. With BAUCOR's dedication to delivering high-quality customized solutions, businesses can stay competitive in today's fast-paced market environment. Embracing tailor-made cutting tools is not just an option but a necessity for those striving for excellence in their manufacturing processes.

English

English