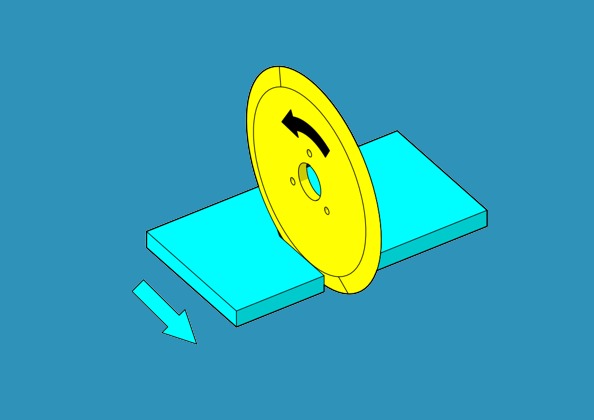

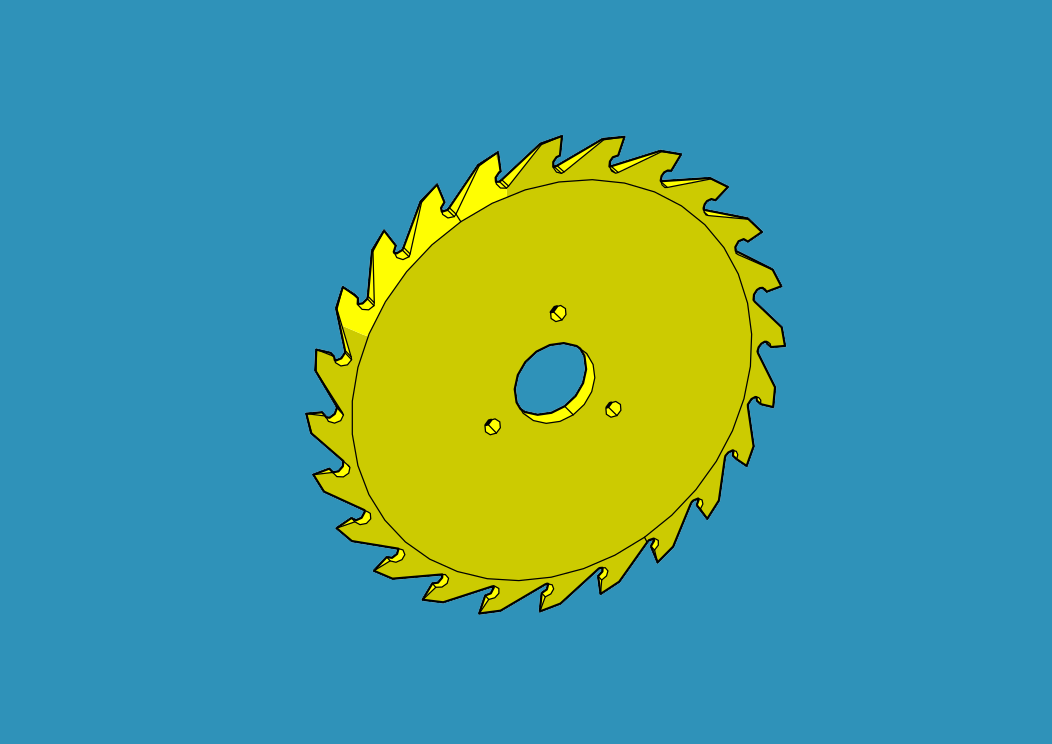

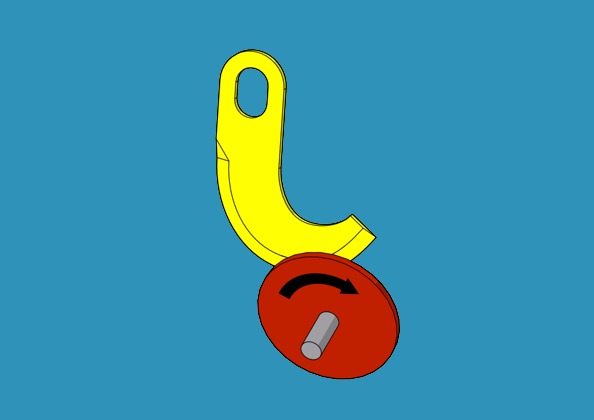

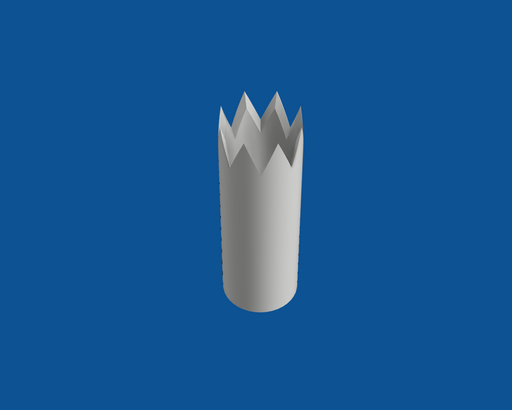

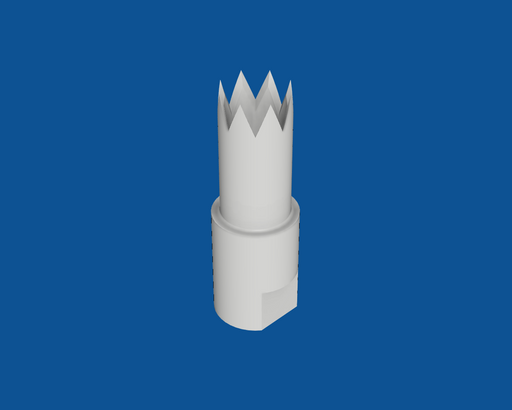

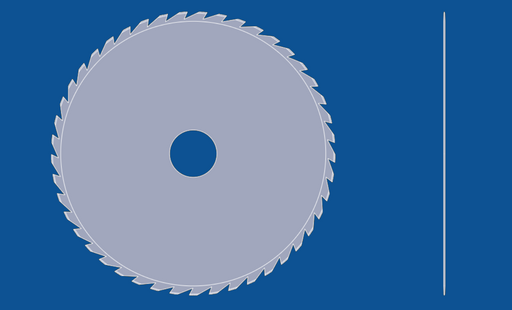

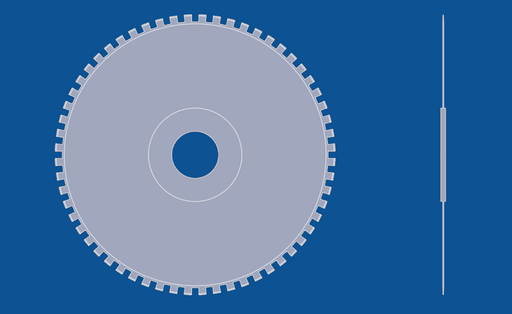

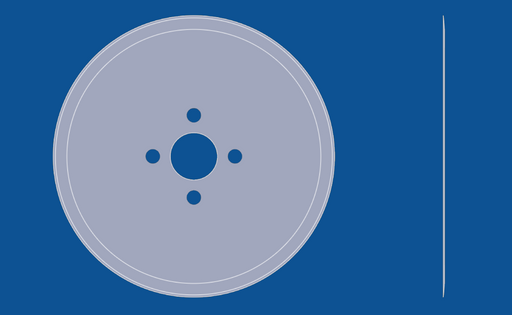

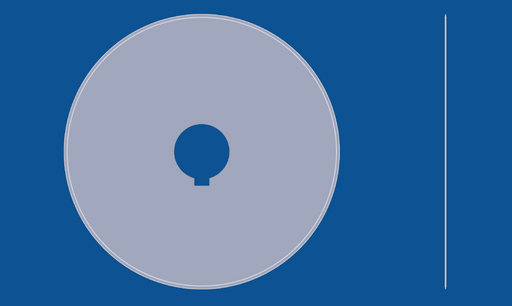

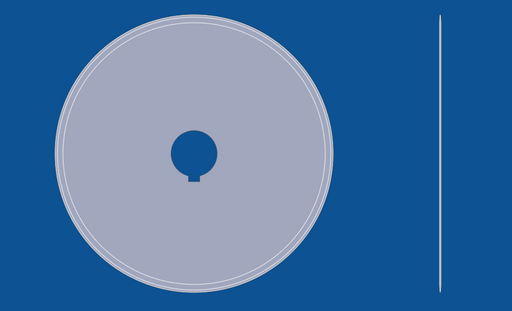

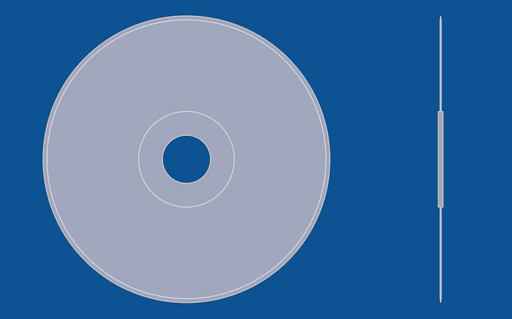

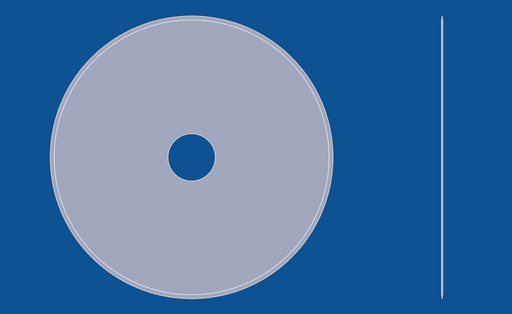

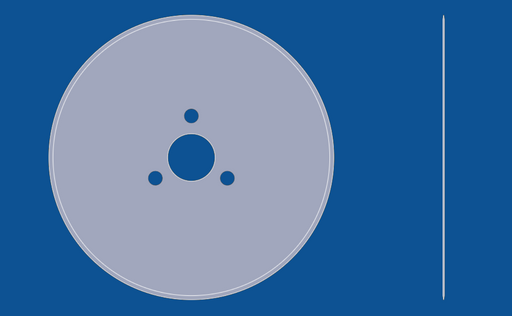

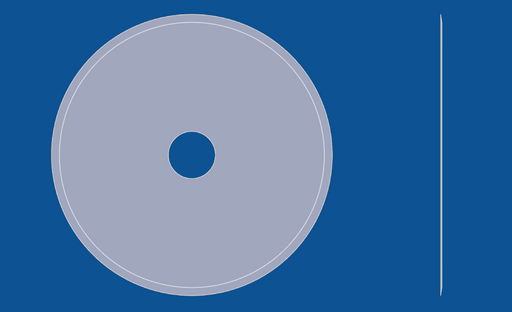

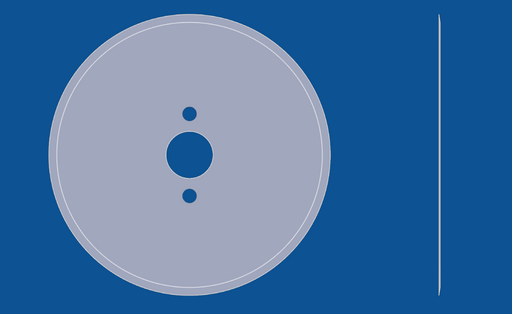

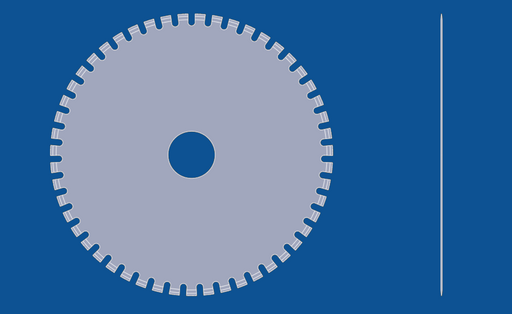

Die-forming tools are essential in the Die-forming tools are essential in the Die-forming process by cutting and shaping metals to the desired size and shape. Die-forming tools are essential in the Die-forming process by cutting and shaping metals to the desired size and shape. Die-forming is a manufacturing process in which a workpiece is shaped by pressing it between two dies using a press. The tools are used to cut the workpiece to the desired shape and size, and they come in various shapes and sizes to meet the needs of different Die-forming applications.

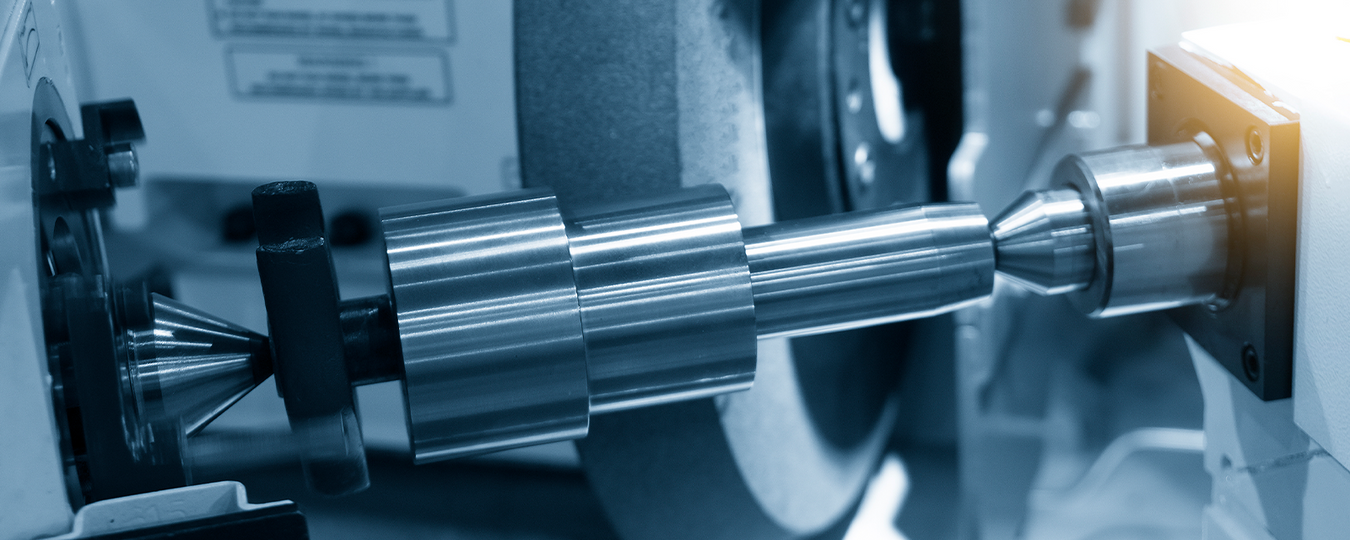

Die-forming tools are typically made from a solid and durable material like stainless steel. This material is resistant to corrosion and can withstand high temperatures.

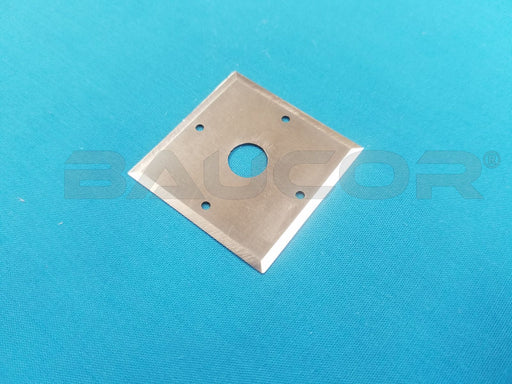

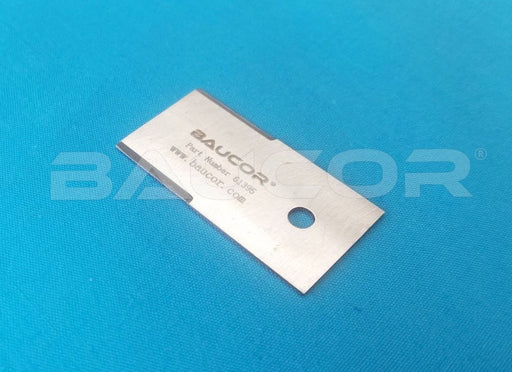

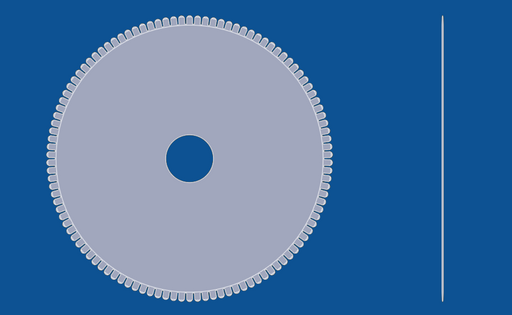

Baucor is one of the leading manufacturer of press knives, DIE cut blades and DIE forming tools that has the capabilities to build and supply highest quality wear resistant parts with strict tolerances. Our press cutting blades, DIE cut knives and DIE forming tools are manufactured from a material of our customer's choice as well as from materials carefully selected by us based on our customers' requirements. Our customers seeking advice on material selection are also provided with in-depth material analysis specifically designed for their cutting proceses.

English

English