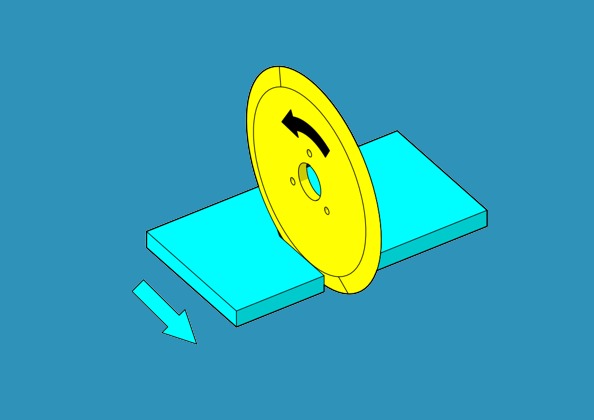

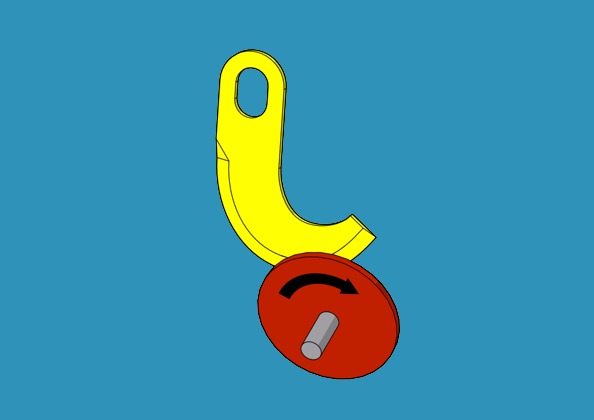

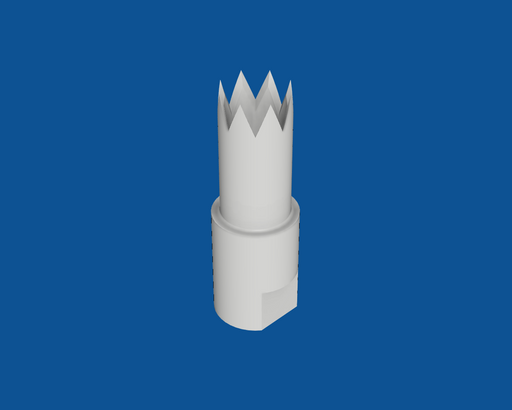

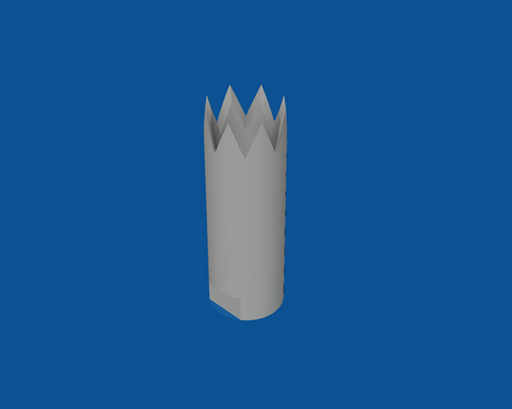

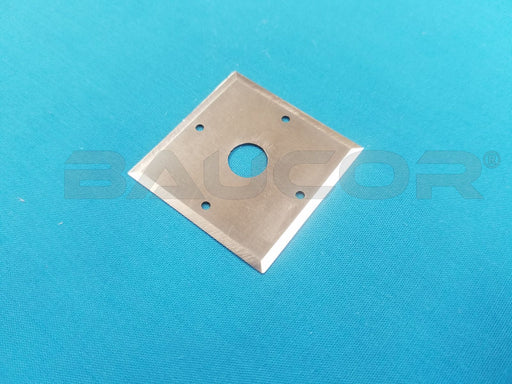

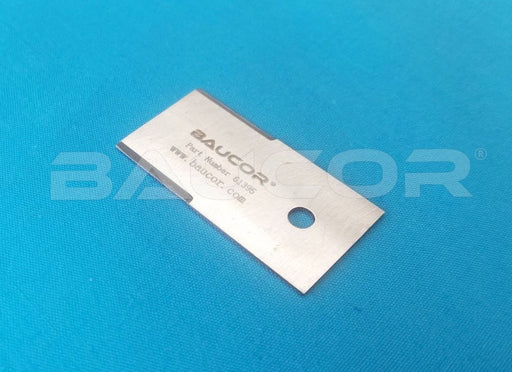

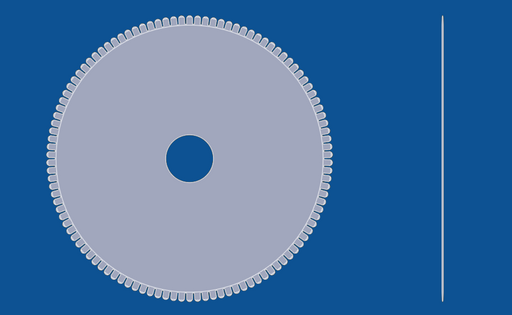

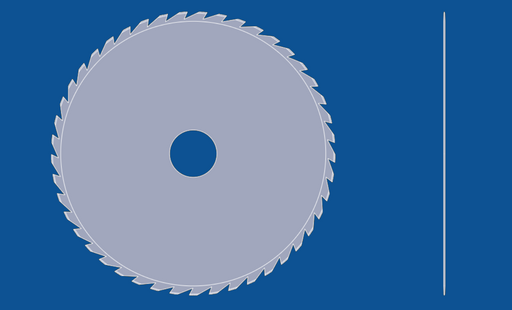

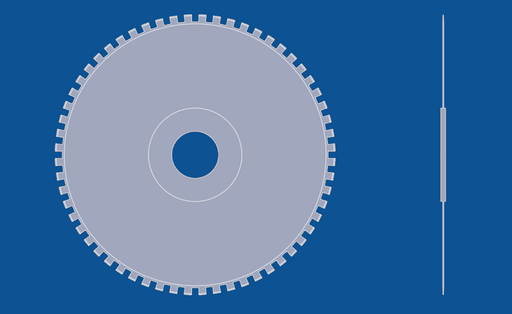

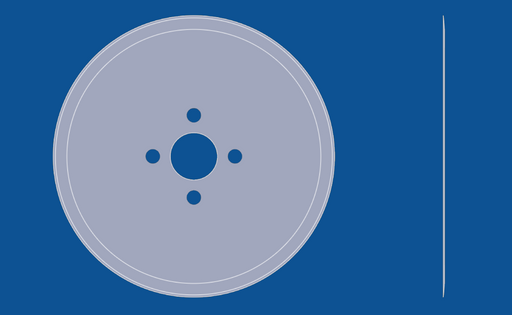

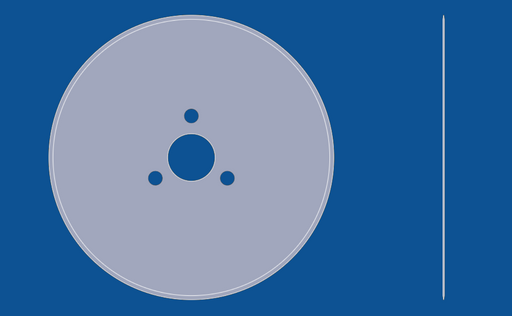

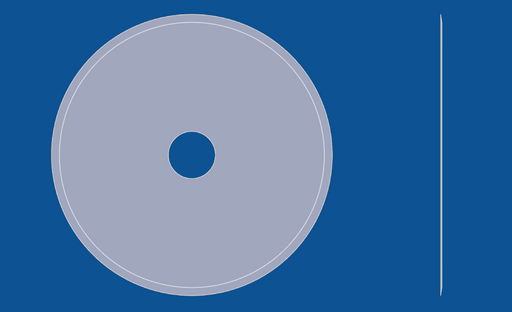

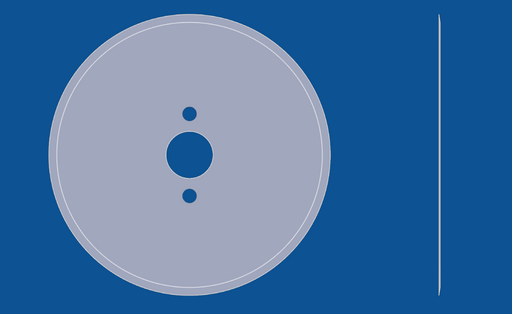

A punch tool is a device that makes holes in materials, including metal, wood, plastic, and more. Baucor offers many punching tools to make almost any hole shape. They are commonly used in food processing, woodworking, metalworking, and other industries that need to make holes in materials.

Punch tools are typically made from high-carbon metals, such as stainless steel, which makes them tough and durable. Some common examples of punch tools include Die punches, hole punches, and leather punches.

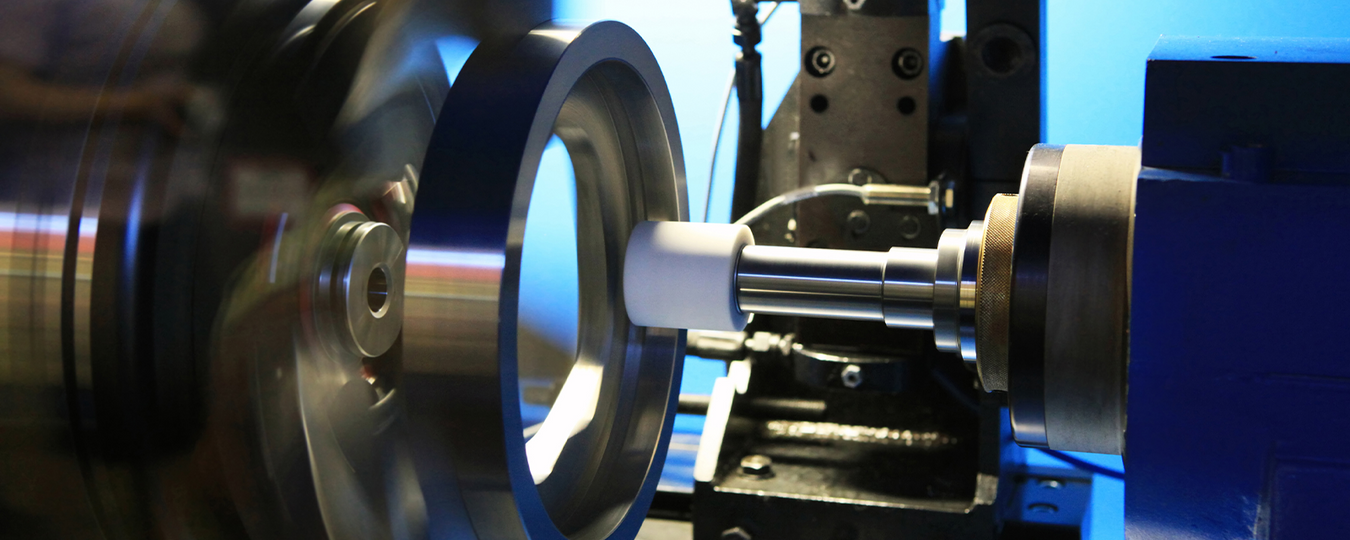

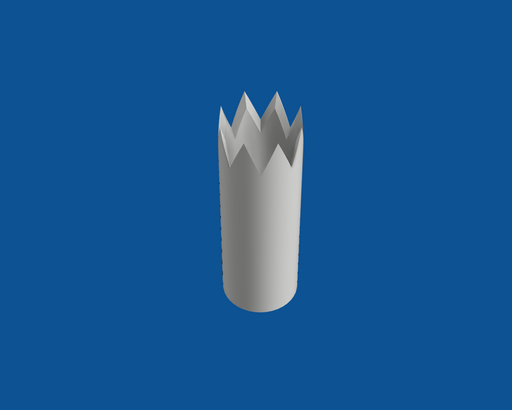

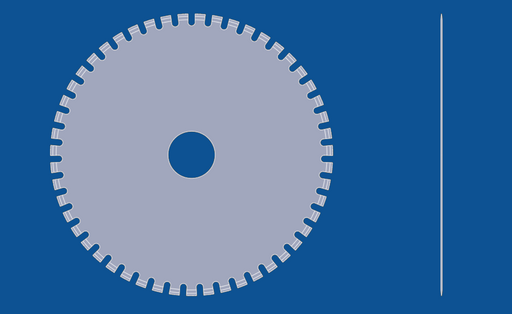

Baucor has the experience to manufacture all shapes and kinds of punch knives, industrial punching tools, press knives, die-cut forming blades. We manufacture and supply literally thousands of both standard and custom size precision punch knives, punching tools, press knives, die-cut forming blades for all kinds of use. Whether you need custom or standard off-the shelf punch knives and die cut blades, Baucor can turn your design into a blade just in days. It doesn't matter if it's paper cutting, packaging, plastic converting, or surgical medical punching, regardless of what it's used for, our punch knives and die cut blades are exceptionally made from quality ground hardened tool steels and stainless steels. If you have a drawing, sample or specifications for the splice knives (splicing blades), please contact us.

English

English