Orthopedic Blade Solutions

Baucor is a leading manufacturer of custom-made surgical blades and medical knives designed to cater to the unique requirements of orthopedic surgeries precisely. We collaborate closely with surgeons, medical device engineers, and industry partners to understand the specific requirements for blades that meet the unique needs of our clients. We use our knowledge and ability to deliver tailored solutions that result in unparalleled satisfaction and success.

What is orthopedic surgery?

Orthopedic surgery is a medical specialty that encompasses diagnosing and treating musculoskeletal system conditions, including bones, joints, muscles, tendons, and ligaments. The surgical procedures performed in orthopedic surgery vary widely and may include joint replacement or spine surgery. Precision and diligence are vital to achieve a successful outcome for patients.

What types of custom surgical blades does Baucor manufacture?

Baucor produces a diverse range of customized surgical blades and saws specifically designed to meet the unique needs of orthopedic surgeries. The individual types of blades available may differ based on the specific requirements of each surgery.

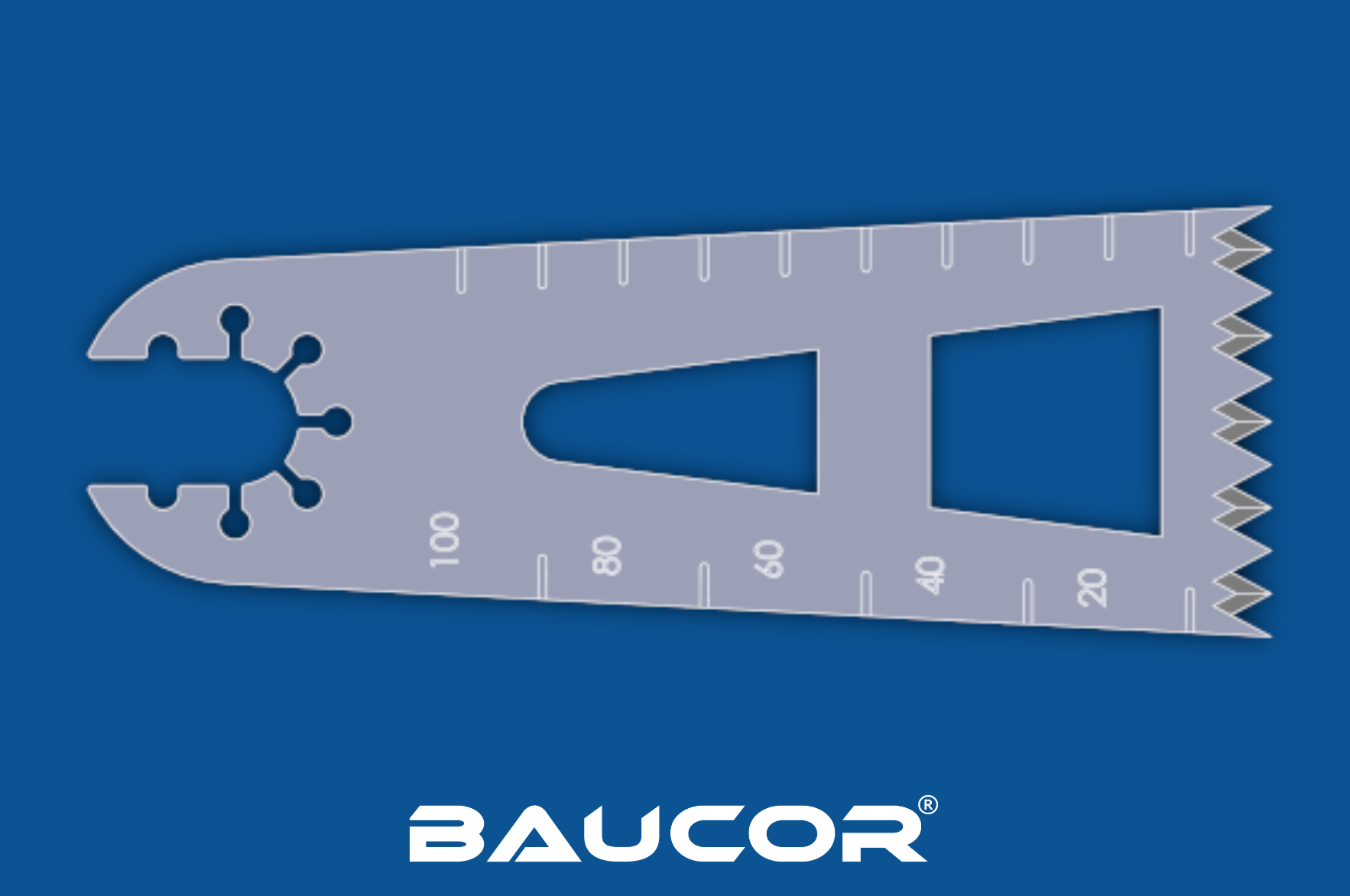

Electric Saw

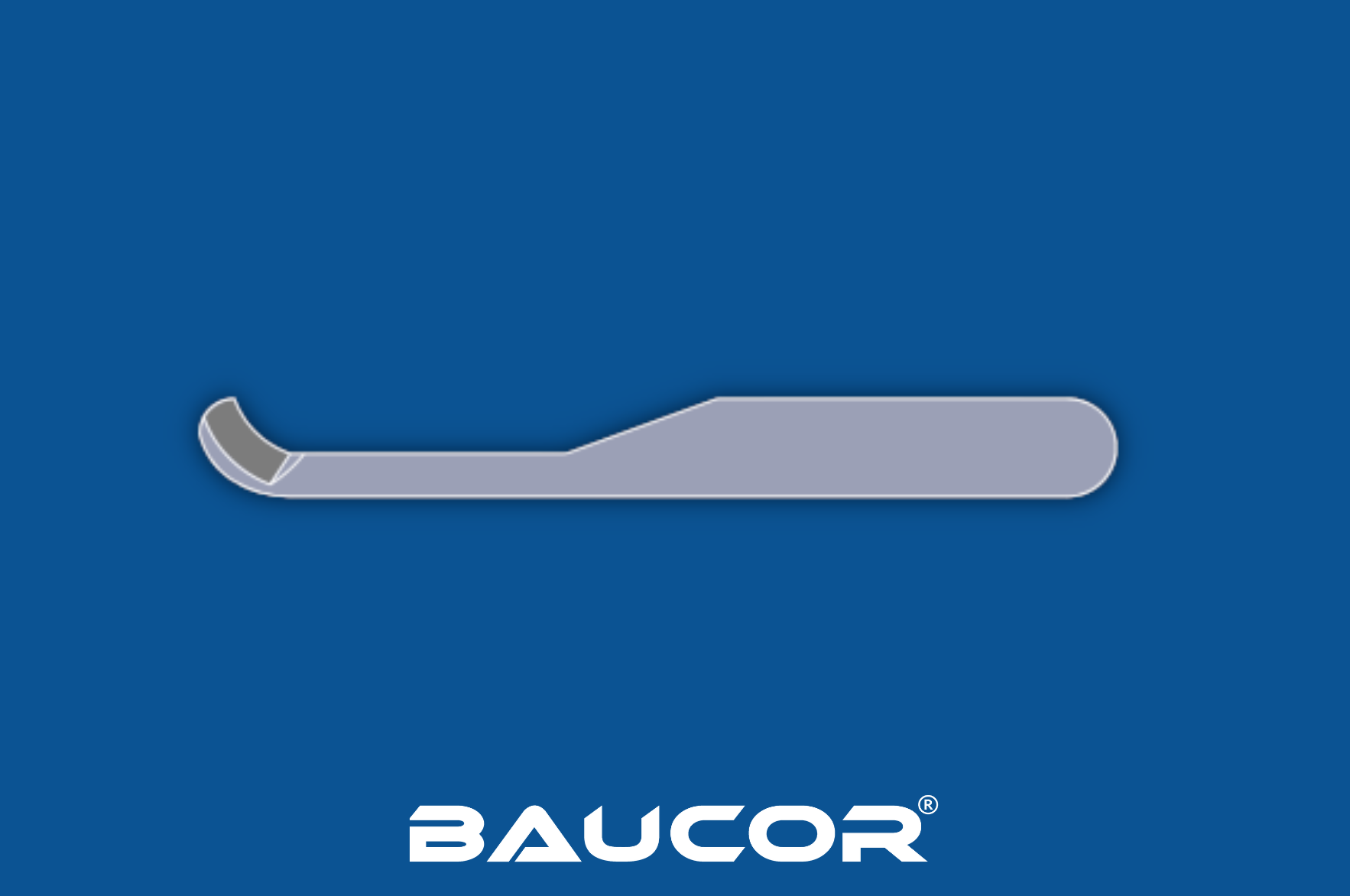

Custom Planning Knife

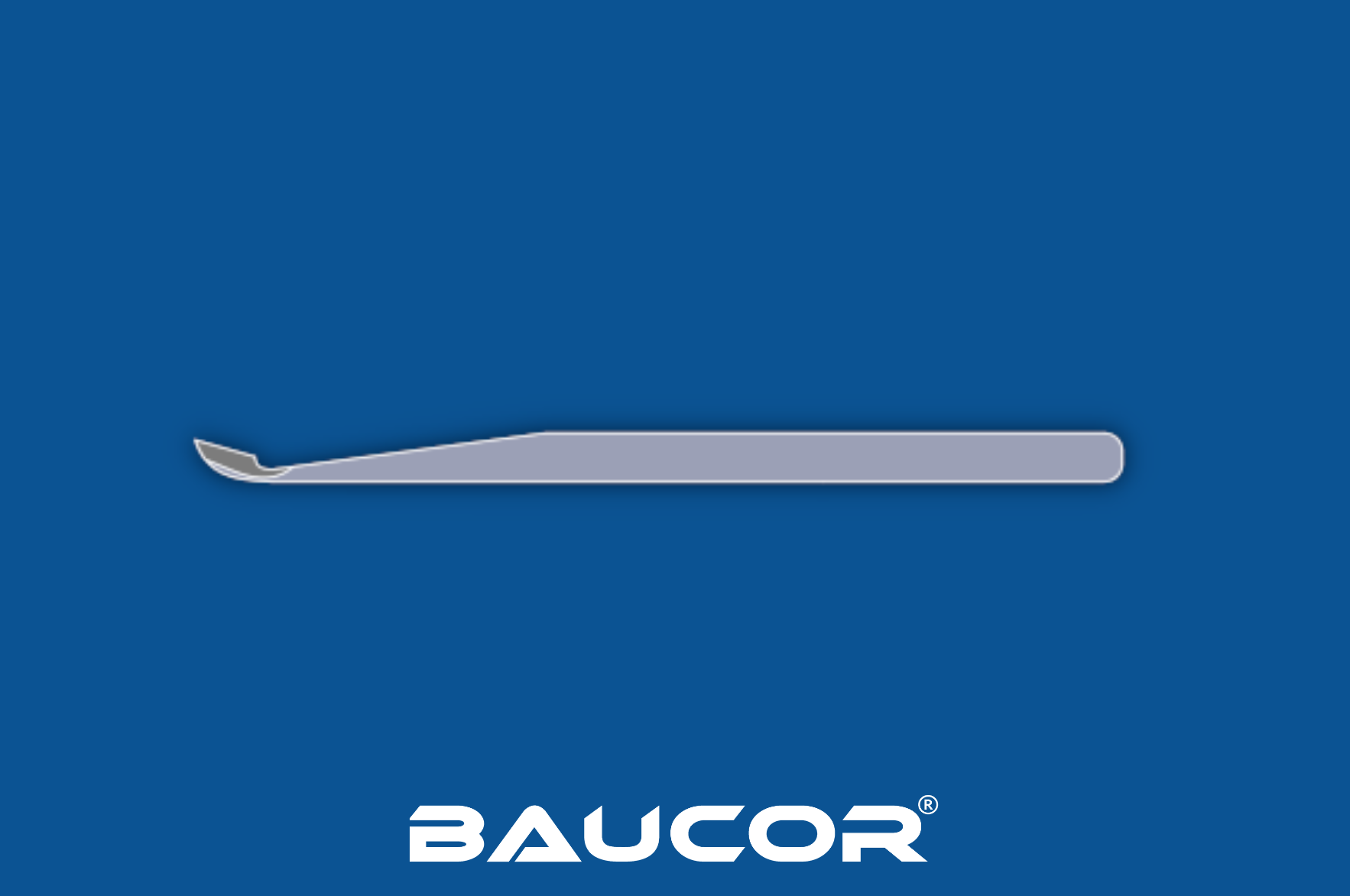

Custom Rosette Knife

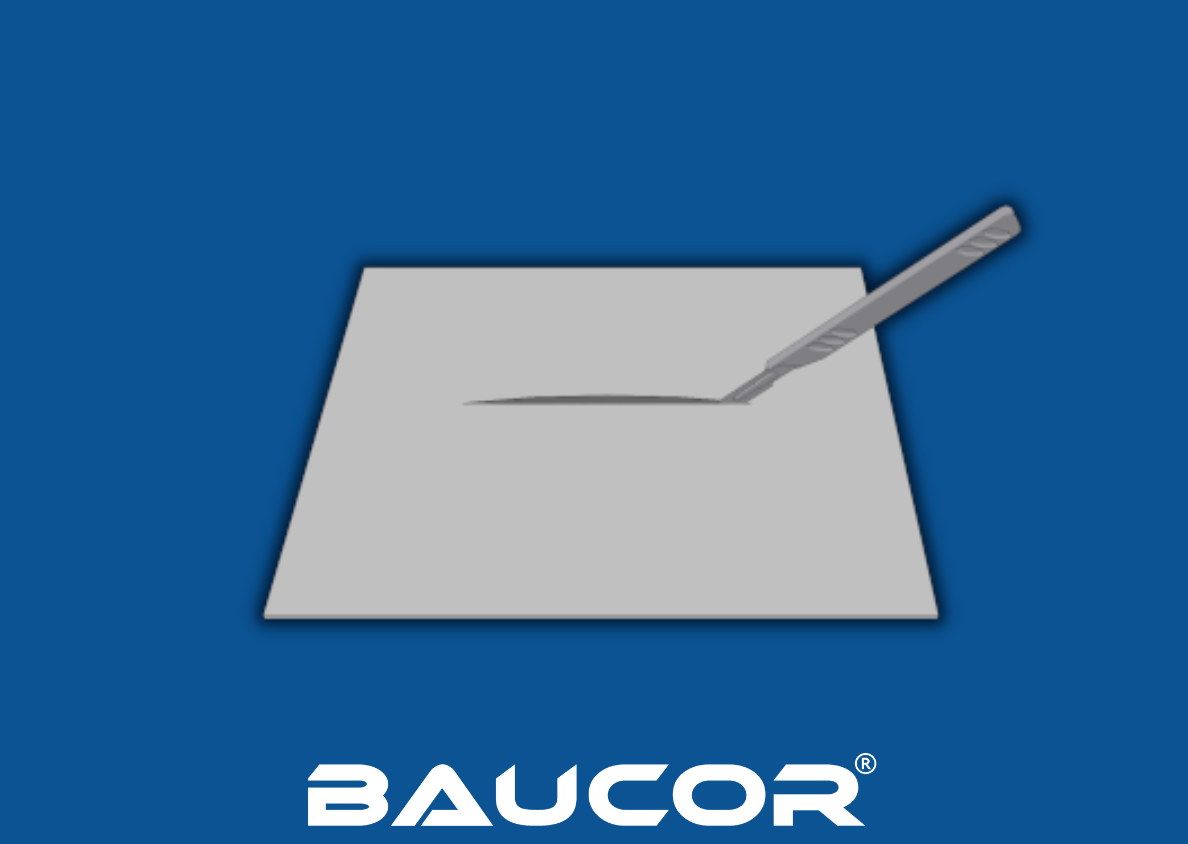

Custom Sickle Knife

GET A QUOTE

How is orthopedic surgery performed?

The process starts with assessing the patient's condition, followed by diagnosis and treatment planning. According to the diagnosis, the patient can get non-surgical interventions (medication and physical treatment). If non-surgical methods are ineffective, the surgeon might recommend surgical intervention.

The surgeon administers anesthesia, makes an incision, and conducts required repairs or replacements during orthopedic surgery to ensure the comfort and safety of their patients.

The success of such surgeries depends on careful planning, precise incisions, and specialized equipment. One of the most crucial tools in these procedures is custom-made blades. These blades are designed to meet the specific requirements of each surgery, ensuring that surgeons have the most effective tools to perform demanding surgeries with precision.

How does Baucor collaborate with industry partners?

We work closely with medical industry partners to develop, improve, and realize custom blades. We offer consultation services such as conceptual design, drafting, CAD design, rapid prototyping, analysis and simulation, and application engineering services such as fabrication, coating, and quality controls. This collaboration allows us to contribute to the advancement of orthopedic surgical techniques.

What are Baucor's quality assurance and regulatory?

Baucor adheres to rigorous quality assurance measures and regulatory compliance standards as a quality product provider of custom-made surgical blades. Our commitment to safety and efficacy guarantees that our products meet or exceed orthopedic surgery requirements, thus providing surgeons with the confidence they need in the operating room.

How are medical blades manufactured?

- Cutting

The first step in manufacturing is to use a CNC machine to cut the blade to the desired shape. - Heating

Next, the blade is put through a heat treatment process to harden the metal and make it more durable. - Sharpening

After heating, the blade is sharpened to remove any imperfections. A grinding process is then used to refine and make the blade sharper. - Coating

By coating the tips of blades with these metals, the blade can better withstand wear and tear. It can prolong the blade's lifespan.

BAUCOR'S CAPACITY & CAPABILITIES

Which material should you use for the blades?

Orthopedic surgery often involves using various materials for custom blades and saws. The choice of material depends on the surgeon’s preference, the surgery's nature, and the instrument's specific requirements. Surgical blades must meet stringent standards for biocompatibility, sterilizability, precision, and durability to ensure the patient’s safety and the success of procedures.

At Baucor, we offer the following materials:

- Stainless steel: The most used material for surgical instruments, including orthopedic blades and saws. It is a durable, corrosion-resistant material and easily sterilized.

- Carbon steel: Another option, it is known for its sharpness and ability to hold an edge well. However, it is less corrosion-resistant than stainless steel.

- Tungsten carbide: It combines tungsten and carbon, giving it exceptional durability and resistance to wear material often used for the tips or edges of blades.

How do medical blades cut?

A medical blade can make the following cuts:

Most used medical blades :

Medical incisions may require various blade shapes based on specific surgical needs.

Conclusion

Our goal at Baucor is to raise the bar for orthopedic surgery. We achieve this by collaborating closely with surgeons, medical device engineers, and industry partners to develop custom blades that meet and surpass the ever-changing demands of the field. Our commitment to delivering high-quality products reflects our dedication to improving patient outcomes.

English

English