PRECISION GRINDING TECHNOLOGY

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

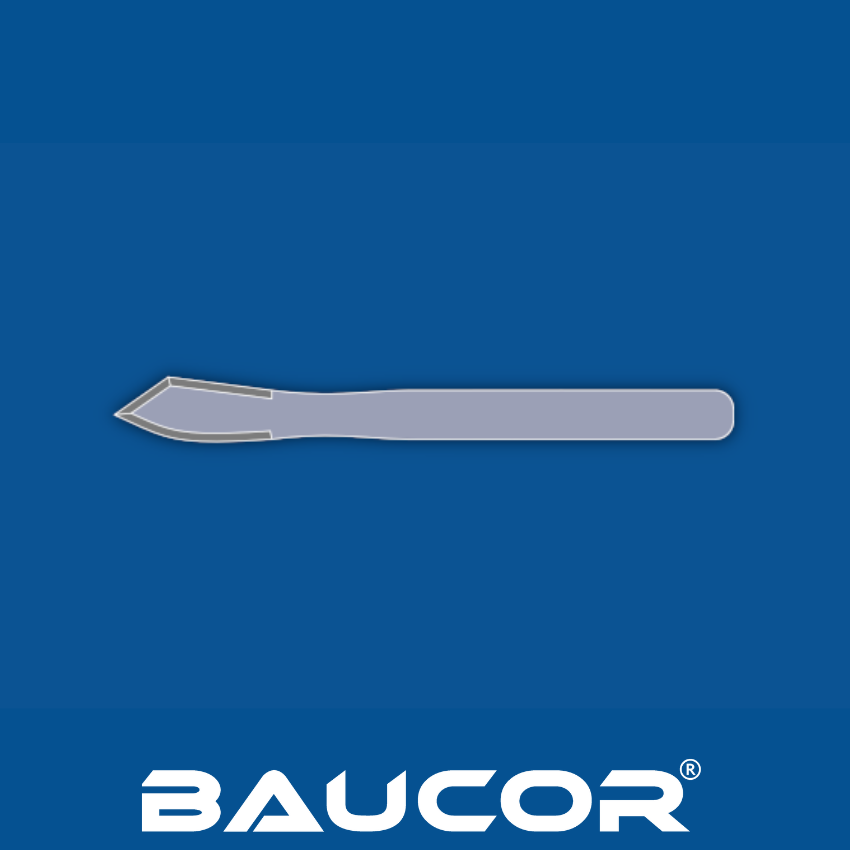

Medical blades come in various shapes and sizes and are used for various procedures, including surgery, diagnostic testing, and tissue sampling.

Custom medical blades are blades that are specifically designed and manufactured to meet the unique needs of a particular medical application.

Custom medical blades are made from high-quality materials such as stainless steel or tungsten carbide. They may be coated with a material such as diamond to improve their wear resistance.

Baucor offers several types of medical blades, including:

* Sometimes the term "medical blade" is used interchangeably with the term "surgical blade".

Baucor is a leading manufacturer of custom-made surgical blades and medical knives designed to cater to the unique requirements of a wide variety of surgeries precisely. We collaborate closely with surgeons, medical device engineers, and industry partners to understand the specific requirements for blades that meet the unique needs of our clients. We use our knowledge and ability to deliver tailored solutions that result in unparalleled satisfaction and success.

Baucor produces a diverse range of customized surgical blades and saws specifically designed to meet the unique needs of a wide range of medical applications. The individual types of blades available may differ based on the specific requirements of each surgery.

Please click on each link to see how Baucor contribues to the advancements in these medical fields with its groundbreaking cutting tools:

From prototyping to high volume production, BAUCOR® provides highest quality technical expertise and capabilities in manufacturing your cutting tools.

BAUCOR® is highly specialized in manufacturing custom industrial blades. If you need your knives manufactured to your exact requirements, please contact us now.

There are many advantages of using custom blades: