Baucor: Meeting Challenges in the Industrial Blade Market

Baucor, a prominent name in the industrial blade market, has a rich history and an impressive establishment. With years of experience, Baucor has become a trusted provider of high-quality blades for various industries. From 71 years, Baucor quickly gained recognition for its commitment to excellence and innovative approach. Over the years, they have expanded their product line to cater to the diverse needs of different industries. From custom-made blades to standard ones, Baucor offers a wide range of options that can meet even the most specific requirements.

Multiple industries must balance industrial blade importance. These blades ensure precision cuts and efficient operations across manufacturing, packaging, printing, food processing, etc. Industrial blades accurately cut metal sheets and plastic components in factories.

Printing presses rely on precise cutting tools to ensure clean edges on paper products. Industrial knives explicitly designed for this purpose enable seamless printing operations with minimal downtime due to maintenance or replacement issues. Food processing is another area where industrial blades are indispensable.

Considering the significant role played by industrial blades across various sectors, having reliable suppliers like Baucor becomes essential. Whether you need circular knives for your packaging line or guillotine knives for your textile factory – Baucor has got you covered! With their extensive range of products and dedication towards customer satisfaction, they have earned their reputation as leaders in the industry.

Industrial Blade Market Overview

Market Trends and Growth

The market for industrial blades is expanding steadily, driven by the growing need for precision cutting across various industries. The global industrial blade market, estimated by recent research reports, was worth USD 8.9 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of roughly 5% to reach USD 12.5 billion by 2026.

Significant firms in this cutthroat market constantly attempt to stay ahead of the curve by developing new products and innovations. Businesses like Baucor have become leaders in the field by using their knowledge to supply premium blades that adhere to industry standards.

Businesses must set themselves apart from rivals in this highly competitive industry. By providing an extensive selection of blades tailored for specific uses in a variety of industries, including food processing, plastics production, packaging, and more, Baucor has been able to accomplish precisely that.

Moreover, technical developments are a significant influence on the market trends for industrial blades. Blades with improved durability, precise cutting edges, and higher productivity are now produced by manufacturers thanks to ongoing advancements in materials science and engineering processes.

Future trends in the industrial blade industry indicate that automation and robotics integration will receive more attention. This move to automated solutions guarantees consistent, high-quality production while increasing productivity and lowering human error.

Demand and Application of Industrial Blades

The need for industrial blades is constantly changing due to the necessity for innovation and industry-specific requirements. Technology breakthroughs have made industrial blades more effective and efficient, allowing companies to suit their specific cutting needs.

Industrial blades are essential for efficient operations in various industries, including printing, food processing, manufacturing, and packaging. These blades are critical in many applications because of their adaptability.

Industry-specific requirements constitute a significant factor in the need for industrial blades. Manufacturers need to have specialized blades made for their particular applications because different industries have distinct needs when cutting products or materials. Precision surgical blades, for instance, that can create neat incisions with minor tissue damage, are needed by the medical sector. Similarly, the paper and pulp industries depend on robust, sharp blades that can meet the demands of high-volume production.

Moreover, innovation is essential to successfully satisfying these sector-specific demands. Producers such as Baucor always continue funding R&D to improve the functionality and design of their blades. By integrating novel materials possessing enhanced hardness or resistance to corrosion in the blade manufacturing process, they can produce items of remarkable caliber that can endure rigorous circumstances.

The industrial blade market is growing as a result of technological improvement as well. Modern industries are seeing a rise in automation, which has led to an increase in the need for robotic systems that have cutting-edge instruments. The industrial blade market in the future will show favorable trends due to technology and industry necessities.

Geographic market segmentation

Geographic market segmentation is crucial to consider, as we have examined the industrial blade market's growth and trends, as well as the need for and uses of these blades across a range of industries. Regarding industrial blades, different parts of the world have distinct needs, and companies such as Baucor may overcome obstacles and take advantage of new opportunities by being aware of these differences.

Leading Regions in Industrial Blade Usage: Several regions are key players in the industrial blade market. North America has been a leader in technological innovation and advancement, home to numerous manufacturing sectors that significantly rely on state-of-the-art blades to run their operations. Europe has a sizable portion of this market as well because of its robust manufacturing sector.

Emerging Markets: In recent years, emerging markets have shown promising potential for growth in terms of industrial blade usage. The Asia-Pacific region, especially nations like China and India, is rapidly industrializing in some different fields. Due to this upsurge, there is a greater need for industrial blades and other effective cutting instruments. Another region seeing industry growth and a growing demand for high-quality cutting solutions is Latin America.

Potential for Growth: A bright future for the global industrial blade market is suggested by the growth of industries such as food processing, packaging, automotive, aerospace, and plastics recycling, to mention a few. Reliable cutting tools will be in demand as these sectors advance technologically and geographically, entering unexplored regions or emerging economies looking for development prospects.

In a highly competitive market where creative solutions tailored to industry demands are essential, Baucor distinguishes itself as one of the top producers of high-performance precision-cutting tools suitable for a wide range of global applications in numerous industries.

Baucor continuously invests in R&D operations to integrate cutting-edge materials with production processes and technology. Baucor has established a robust presence in prominent regions such as North America and Europe, along with rising markets in Asia-Pacific and Latin America, owing to its unwavering dedication to quality, performance, and customer satisfaction.

Baucor is well-positioned to sustain its growth trajectory not only in these top regions but also in other prospective growth markets globally, thanks to its unwavering pursuit of excellence.

GET A QUOTE

Challenges in the Industrial Blade Market

Material and Manufacturing Challenges

Material selection is a crucial aspect of the industrial blade market. Solid, quality materials are needed to make blades that withstand harsh industries.

Blades have to stay sharp and intact for long periods, whether they are cutting through hard metals or slicing through delicate materials.

It might be challenging to find the ideal material that combines toughness, wear resistance, and hardness in just the correct amounts. To determine which material is best for a given application, manufacturers frequently need to go through a thorough investigation and testing process.

Precision and consistency in production processes are just as critical as material difficulties. Industrial blades need to be created with the highest level of accuracy to guarantee consistency in every piece. Even a tiny divergence might cause performance irregularities and worse overall quality.

Sustaining uniform blade profiles, sharp edges, and dimensional accuracy necessitates sophisticated equipment and knowledgeable operators who understand complex manufacturing processes. But even with meticulous attention to detail, variations could still occur throughout production that require close observation and modification.

The market for industrial blades is constantly changing due to the development of new materials and production techniques.

Technological Advancements and Innovation

Keeping up with industry trends and technological shifts is critical to staying competitive in the industrial blade market. Because technology is developing so quickly, businesses like Baucor must make research and development investments.

A vital component of satisfying consumer wants is innovation—the need for industrial blades changes along with the industry. Embracing innovation enables businesses to tackle these changing needs head-on, whether creating novel blade geometry for increased precision or cutting-edge coatings to increase longevity.

Baucor ensures it can fulfill its clients' changing needs by implementing new technology, investigating cutting-edge materials, and continuously refining its manufacturing methods. Their dedication to invention enables them to create blades that are not only long-lasting and of superior quality but also tailored for specific uses.

By foreseeing potential obstacles in the industrial blade market, research and development expenditures help Baucor remain ahead of the curve. Through an analysis of developing patterns and a grasp of client requirements, they can preemptively devise strategies that confront these obstacles.

Baucor is aware of the difficulties that companies in the industrial blade industry encounter. Furthermore, by consistently allocating resources towards research & development, they guarantee that they stay at the forefront of technical breakthroughs in the sector.

Competition and Price Pressures

Businesses in the fiercely competitive industrial blade market must contend with fierce competition from long-standing rivals and recent arrivals. Customers have many options at their disposal; therefore, businesses need to work to stand apart from the competition constantly.

Price pressure is one of the main obstacles in this competitive environment. Consumers constantly search for economical options that deliver value without sacrificing effectiveness or quality. Companies must carefully balance the requirement to sustain profitability with their pricing strategy to survive and grow in this market.

Businesses frequently spend money on R&D to innovate and create cutting-edge products that satisfy consumer wants to address these issues. By keeping up with technological advancements and market trends, businesses can make sure they are providing advanced solutions that offer them a competitive advantage.

Moreover, acquiring a competitive advantage depends mainly on employing efficient marketing techniques. Businesses must convey to customers why their blades are superior to their rivals.

Competition and price restraints plague the industrial blade business. However, companies can not only survive but also prosper in the face of intense competition if they consistently pursue innovation and provide affordable solutions while upholding high-quality standards.

Regulatory and environmental challenges

Operating in the industrial blade market entails several regulatory and environmental concerns. Manufacturers must always ensure that their products meet all safety and quality requirements by adhering to industry standards and regulations.

Compliance is about maintaining a commitment to sustainability and environmental responsibility, not merely checking boxes. As technology develops, so are the demands placed on businesses to reduce their environmental footprint. It entails creating eco-friendly and highly efficient blades using materials and production techniques that minimize waste and emissions.

Manufacturers need to be proactive to meet these problems. It entails keeping up with the industry's changing rules and actively participating in continuous research and development initiatives to identify creative solutions that support sustainability objectives.

Manufacturers may meet consumer demands for greener products and establish themselves as leaders in environmental stewardship by embracing sustainable practices early on.

Manufacturers of industrial blades must constantly adjust to changing regulations and environmental concerns. In today's environmentally concerned market, organizations need to pursue sustainable practices to stay competitive actively. More than simply adhering to norms is required.

How Baucor is Meeting These Challenges?

Investment in Research and Development

At Baucor, they understand that staying ahead of the game in the industrial blade market requires constant innovation and a keen eye for industry trends. They make significant R&D investments to create novel materials and technologies that push boundaries and improve performance.

Their team of professionals is committed to investigating novel approaches that not only satisfy the needs of the industry now but also foresee its demands in the future. The Baucor team can spot areas for development and stay ahead of the curve by attentively observing market trends, consumer input, and new technology.

They encourage our bright engineers to think creatively, try out novel concepts, and work across departmental boundaries. Their ability to work together fosters innovation and enables us to create ground-breaking breakthroughs in blade technology.

Moreover, they regard ongoing education as an essential component of their dedication to research and development. The company staff frequently engages in industry conferences, seminars, and workshops as a means of exchanging expertise with colleagues worldwide.

Using innovation-driven techniques and a relentless focus on research and development, Baucor hopes to not only address current issues but also to influence the industrial blade market's future.

Quality Assurance and Precision Manufacturing

Regarding industrial blades, quality, and precision are of utmost importance. Knowing this, Baucor has established stringent quality control procedures to guarantee that its goods live up to the greatest expectations.

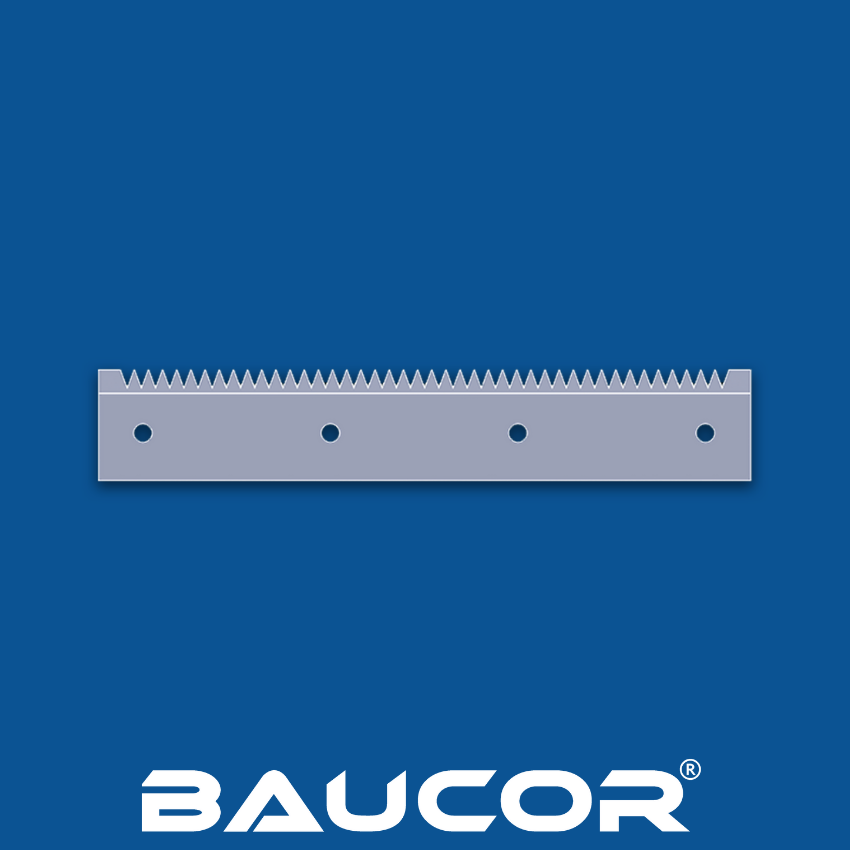

When designing a blade, Baucor pays close attention to every little detail. Their team produces blades with remarkable accuracy and consistency using cutting-edge manufacturing methods. They can make precise and long-lasting blades thanks to advanced machinery and equipment.

Baucor can supply blades that continuously outperform competing ones on the market by making investments in state-of-the-art technology and upholding strict quality control procedures. Customers can count on Baucor to provide them with premium blades that will cut through paper, plastic, and even food items with ease and effectiveness.

Baucor distinguishes itself in a field where accuracy is crucial by offering unparalleled attention to detail throughout its manufacturing processes. Their commitment to quality assurance distinguishes them from rivals and establishes them as a reliable partner for companies operating in various global areas.

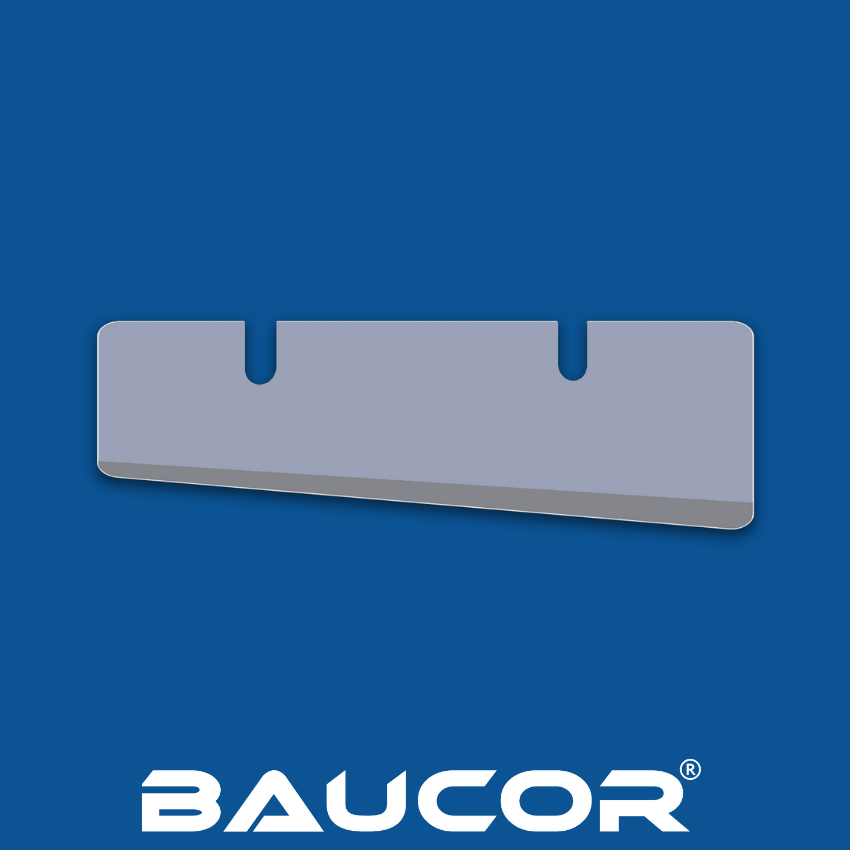

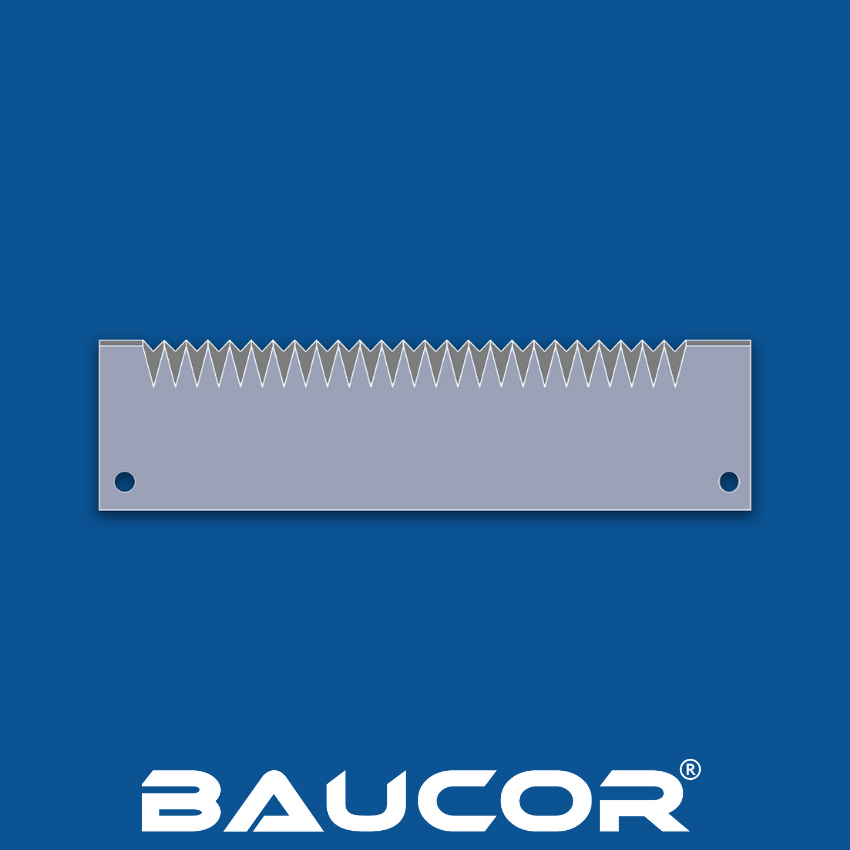

Diverse Product Range and Customization

Baucor understands that different industries have unique needs and requirements for their cutting applications. To ensure a blade solution for any business, they offer a wide range of products. Baucor has you covered whether you work in the medical area, the packaging industry, the food processing industry, or any other industry that needs precise cutting instruments.

But, their dedication to offering specialized solutions makes them stand out from others in the industry. They know that sometimes customized client requirements may only partially be addressed by off-the-shelf products. In these situations, Baucor collaborates closely with customers to provide custom blades ideal for their needs.

Their team of professionals pays close attention to the requirements provided by the client and applies their wealth of knowledge and expertise to create blades that function at their best. During the customized process, every detail is carefully considered, from material selection to production procedures.

Furthermore, Baucor guarantees the prompt and precise delivery of these bespoke solutions. Their cutting-edge manufacturing facilities, furnished with sophisticated machinery, enable efficient production while upholding superior quality standards.

Baucor is a leader in the industrial blade industry because of its wide range of products and ability to customize services to meet the needs of individual clients.

Global Presence and Market Adaptation

Expanding reach to different geographic markets is a crucial aspect of any business's growth strategy. Baucor understands the value of having a presence in multiple areas and modifying its offerings and business plans to suit regional demands.

Baucor will be able to take advantage of new opportunities and serve a more extensive clientele by growing its global footprint. They can lessen their reliance on particular markets or industries and diversify their consumer base.

In today's competitive marketplace, it is imperative for success to tailor strategies and goods to the specific needs of local markets. Baucor knows that an effective solution in one area might not be the best in another. They can recognize distinct consumer preferences, cultural quirks, and industry requirements by carefully examining each market.

Because of its capacity to adjust, Baucor stands out from its rivals and can suit the unique needs of every market it enters. Baucor goes above and beyond to customize its products, whether it means changing the patterns of blades or altering the manufacturing procedures.

Furthermore, Baucor guarantees compliance with all criteria in each target market thanks to its in-depth knowledge of local rules, certifications, and standards. They have a competitive edge because of their attention to detail, which builds confidence with clients who respect upholding quality standards.

Baucor has demonstrated its commitment to providing excellent service globally by extending its global footprint and adjusting its goods and tactics based on local market needs. Using this strategy, they foster solid bonds with clients in various international businesses.

Commitment to Sustainability and Compliance

Baucor is serious about upholding compliance and sustainability. In a world that is constantly changing and where environmental issues are at the forefront of many businesses, Baucor recognizes the value of integrating sustainable practices into operations and manufacturing.

For Baucor, sustainability is more than just a catchphrase; it is fundamental to their business. They actively look for ways to use less energy, less waste, and eco-friendly materials whenever possible to lessen their carbon footprint. Their focus on sustainability ensures that their products are of the best quality and environmentally friendly.

Another area in which Baucor shines is regulatory compliance. They know that upholding industry rules is essential to preserving the confidence and trust of clients. They invest significantly in research and development to stay abreast of changing requirements to assure compliance.

Furthermore, Baucor routinely carries out internal audits to evaluate its procedures in comparison to legal mandates. They can quickly detect any areas of non-compliance and take appropriate action because of their proactive attitude.

Baucor distinguishes itself in the industrial blade industry by fusing environmentally friendly operations with rigorous attention to legal requirements. Their commitment to upholding the law and being ecologically conscious shows they are committed to creating a better future for all parties involved, including suppliers, consumers, employees, and the environment.

GET A QUOTE

Conclusion

To sum up our exploration into Baucor's triumphs success in the industrial blade market, it's evident that this company is a force. Their relentless pursuit of excellence and ability to overcome challenges have set them apart from their competitors.

Baucor's commitment to innovation shines through in every aspect of their business. From designing and manufacturing high-quality blades that meet the specific needs of each customer to embracing new technologies and cutting-edge techniques, Baucor consistently pushes boundaries and sets new industry standards.

Baucor has repeatedly proven that they are up for any challenge. Their unwavering commitment to delivering top-notch products and services has earned them a reputation as an industry leader. As businesses rely on precise cutting solutions, Baucor will undoubtedly remain at the forefront, constantly pushing boundaries and setting new benchmarks for excellence in the industrial blade market.

English

English