Precision Industrial Blade and Knife Manufacturing and How BAUCOR Contributes to it

This industry is crucial in various sectors, from food processing to packaging, rubber and plastic industries, medical device production, and many more. Precision is critical when creating these essential tools for cutting materials with accuracy and efficiency.

Manufacturers like BAUCOR contribute significantly to this field by utilizing advanced technologies and expertise in producing high-quality industrial blades tailored to specific needs. Innovation drives this industry forward as manufacturers continuously explore new materials, designs, and techniques to enhance the functionality of industrial blades. With constant research and development efforts, we can expect even more sophisticated and efficient industrial knives.

The Importance of Quality Manufacturing in the Industrial Blade Industry

High-quality production is essential to achieving maximum performance and longevity in the industrial blade sector.

Industrial blades are high-precision instruments with various uses, including material cutting and shredding. The quality of these blades directly impacts the efficacy and efficiency of industrial processes.

Manufacturers may create more accurate, dependable, and long-lasting blades by investing in superior production techniques. It lowers maintenance expenses and downtime while also improving overall performance.

Moreover, superior manufacturing guarantees that industrial blades fulfill stringent industry requirements for dependability and safety. It is particularly significant for businesses where consistent, high-quality products depend on precision cutting.

Putting quality manufacturing first in the industrial blade sector is crucial to increasing output, lowering risks, and producing better outcomes.

BAUCOR: A Leader in Precision Industrial Blade and Knife Manufacturing

BAUCOR is a clear industry leader in manufacturing knives and precision industrial blades. With years of experience and knowledge, BAUCOR has established a solid reputation for manufacturing knives and blades of the finest caliber and performing to the highest standards.

BAUCOR is unique because of its dedication to cutting-edge technology and innovation. They can reliably provide goods that surpass client expectations through constant innovation in production methods.

The dedicated engineers and technicians at BAUCOR work nonstop to guarantee that every blade and knife manufactured satisfies their exacting quality control requirements. Every stage of the manufacturing process, from the initial design to the finished product, is closely supervised to ensure quality in each piece.

Whether you require bare blades for everyday use or specialized blades for a particular purpose, BAUCOR provides various customization choices to meet your requirements. They stand out from other manufacturers in the sector because of their capacity to customize items to meet customers' needs.

Look no further than BAUCOR if you're searching for high-quality, high-performance industrial knives and precision blades.

BAUCOR's State-of-the-Art Manufacturing Process

Modern production methods set BAUCOR apart in the precise industrial blade and knife industry.

Modern machinery and technology are featured in BAUCOR's manufacturing plant, guaranteeing the production of items of the most extraordinary caliber. Every stage, from design to production, is painstakingly and precisely carried out.

The company's knowledgeable engineers and technicians collaborate to realize creative concepts and push boundaries within the sector. Based on accuracy and efficiency, BAUCOR provides excellent satisfaction in customizing premium knives and blades to match individual customer requirements.

BAUCOR continuously improves its production process by investing in research & development to keep ahead of the curve. Their dedication to innovation distinguishes them as a frontrunner in the industrial blade production sector.

Clients can be assured that when they select BAUCOR, every step of the production process is carried out with skill and attention to detail.

GET A QUOTE

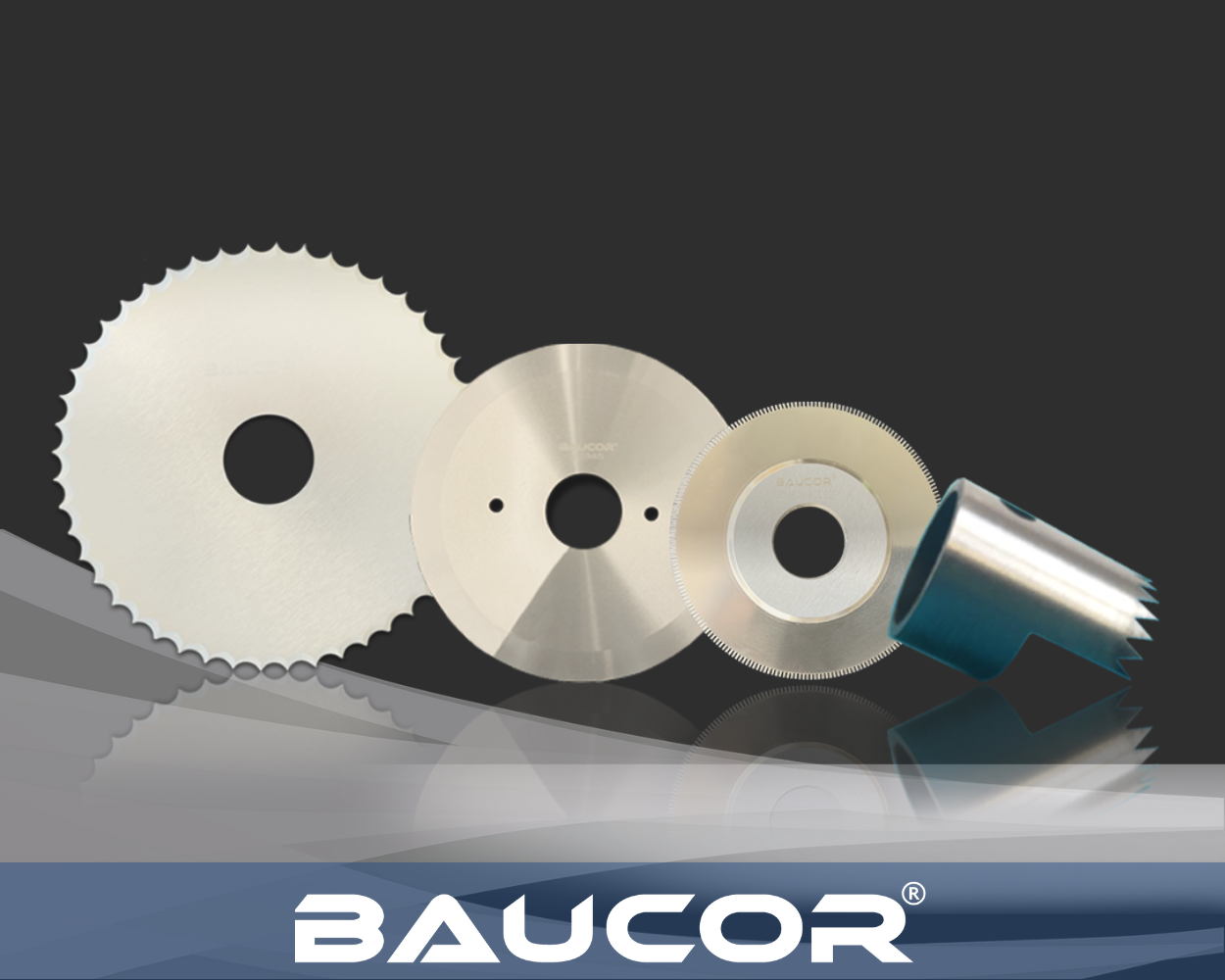

Types of Industrial Blades and Knives Offered by BAUCOR

As a well-known brand in the industrial blade and knife manufacturing business, BAUCOR offers various innovative products designed to cater to the demands of different industries. The extensive selection of industrial blades and knives the company offers proves its dedication to accuracy and excellence

1. Industrial Razor Blades:

BAUCOR manufactures industrial razor blades renowned for their longevity and sharpness. These razor blades are used in fields where accuracy is crucial, such as printing, packaging, and converting. Because the razor blades are expertly made, they will operate optimally when cutting in tough conditions.

2. Machine Knives:

BAUCOR makes machine knives ideal for various cutting tasks, such as metalworking and cutting fabrics and plastics. These knives are made with cutting-edge materials and undergo a strict quality control process to ensure accuracy and durability. The wide variety of machine knives meets the changing requirements of contemporary production methods.

3. Circular Knives:

In several sectors, such as foil, film, and paper conversion, circular knives are indispensable. The circular knives made by BAUCOR are expertly manufactured, enabling precise and effective cutting. Whether cutting, perforating, or scoring, these knives are designed to function with dependability and consistency.

4. Custom-Designed Cutting Solutions:

BAUCOR provides custom-designed cutting solutions in recognition of the distinct needs of various sectors.

With the help of this customized strategy, the business can work closely with customers, getting to know their unique requirements and making knives and blades compatible with their manufacturing procedures. Because of its unique flexibility, BAUCOR is the go-to option for companies looking for specialized cutting tools.

Advanced Manufacturing Techniques Used by BAUCOR

BAUCOR sets itself apart as a significant participant in the industrial blade and knife manufacturing market by using cutting-edge production techniques. These methods play a crucial role in guaranteeing the accuracy, caliber, and effectiveness of the goods the business provides to its customers.

Computer Numerical Control (CNC) machining technology lies at the core of BAUCOR's advanced production processes. This innovative method allows industrial blades and knives to be machined with extreme precision and automation.

CNC machines make it possible to create complex designs with precise tolerances, guaranteeing that every product fulfills the exact requirements set forth by the customers. Because of its unmatched precision in producing complicated and sophisticated cutting tools, BAUCOR stands out in the industry thanks to its use of CNC machining technology.

Robotics and automated systems are integrated into BAUCOR's manufacturing facilities to improve uniformity and efficiency. These devices reduce human error, expedite the production process, and improve the accuracy of each cut. By using robots, BAUCOR guarantees the highest quality standards for its industrial knives and blades, enhancing the dependability of these instruments in various production applications.

By using cutting-edge alloys and high-performance materials to produce its blades and knives, BAUCOR maintains its position as a leader in material innovation. The goods' overall performance, sharpness, and longevity are all improved by this dedication to material quality. BAUCOR keeps its cutting tools at the forefront of industrial technology by keeping up with developments in material science.

At every level of the manufacturing process, BAUCOR implements strict quality control procedures to maintain its reputation for producing high-quality products. It involves putting every industrial blade and knife through rigorous testing, inspections, and certification. By strictly adhering to quality control procedures, BAUCOR ensures its products meet and surpass industry standards.

Customization Options for Precision Industrial Blades and Knives

Customization is essential when it comes to industrial blades and knives with precision. At BAUCOR, they are aware that every sector has particular requirements and demands that call for customized solutions. They provide many customization choices to ensure clients receive precisely what they require.

Their skilled staff can collaborate with you to design the ideal blade for your application, considering everything from blade material and coatings to edge geometry and tooth combinations. Whether you require a standard-sized blade or a fully customized design, we can make your idea a reality.

They can manufacture superior precision blades with unparalleled consistency and accuracy because of our cutting-edge production method. The company can meet even the most exacting specifications since we have skilled artisans and state-of-the-art CNC grinding machines.

You can be sure that the precision industrial blade customization you need from BAUCOR will be long-lasting and of the highest caliber.

GET A QUOTE

Advancements in Technology for Precision Blade Manufacturing

Technology has transformed the production of precision blades, pushing boundaries and creating new benchmarks. Modern equipment, such as multi-axis CNC machines, has revolutionized the manufacturing of industrial blades by enabling previously unheard-of levels of consistency and precision.

Additionally, industrial knives have better cutting capability and durability because of cutting-edge materials like ceramic and high-speed steel. Automation is essential for cutting lead times, improving productivity, and optimizing production processes.

Moreover, advancements in coating technologies such as DLC (Diamond-Like Carbon) coatings offer enhanced resistance to wear and prolong the life of precision blades. Before actual production starts, producers can easily create complex blade geometries with 3D modeling software.

By pushing the limits of precision blade manufacture, these technical developments guarantee that businesses obtain high-quality products tailored to their particular requirements.

As we look towards the future of precision industrial blade manufacturing, one thing is sure - BAUCOR will continue to lead the way with its dedication to excellence and customer-centric approach. Whether developing new materials or improving existing designs, BAUCOR remains committed to pushing boundaries and setting new standards in the industry.

English

English