UNLOCK SUPERIOR CUTTING POWER WITH BAUCOR END MILLS

PRECISION ENGINEERING AT ITS BEST!

UNLOCK SUPERIOR CUTTING POWER WITH BAUCOR END MILLS

PRECISION ENGINEERING AT ITS BEST!

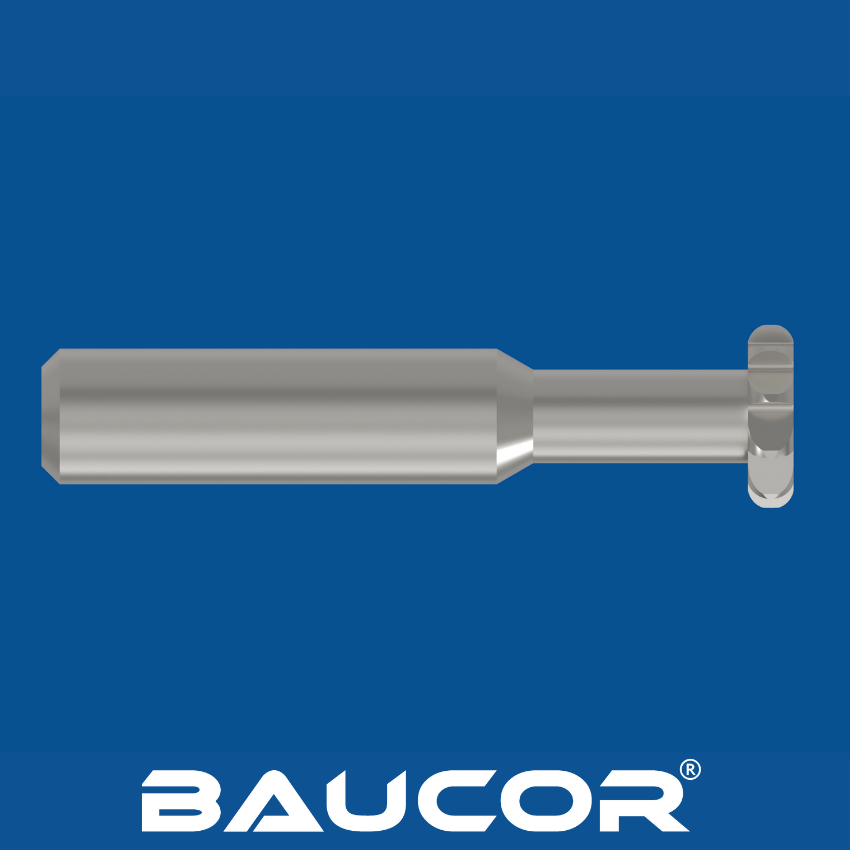

What is a Full Radius Keyseat Cutter?

Full radius keyseat cutters are specialized milling tools designed to create semi-circular keyseats within shafts or bores. These keyseats have a rounded bottom profile, offering several advantages:

Easier Machining: Rounded profiles can often be cut without sharp corner transitions, simplifying the machining process.

Baucor – Your Source for High-Quality Full Radius Cutters

Baucor manufactures full radius keyseat cutters engineered for precision and durability. We offer cutters in various materials (HSS, carbide) to suit your workpieces. Baucor can craft custom cutters for unique keyway dimensions or applications. Our experts guide you in selecting the optimal cutter and machining parameters.

Key Manufacturing Processes

Standard Size Ranges

Baucor likely offers a comprehensive range of full radius keyseat cutters to accommodate common industrial applications. Here's a breakdown of typical sizes:

Metric:

Imperial

Factors Affecting Size Selection

Baucor can manufacture end mills to cater to a diverse range of milling applications, from general purpose milling tasks to the creation of intricate profiles and complex 3D shapes.

End mills are available in a variety of types, such as square end mills for creating sharp corners, ball nose end mills for smooth contouring, and roughing end mills for rapid material removal. Suitable for materials including metals, plastics, and composites, Baucor can produce end mills in highly specialized sizes and configurations tailored to meet your specific requirements. Please contact us for detailed information on dimensions and customization options to perfectly match your milling needs.

Choosing the Right Material for Your Application

The optimal material for a full radius keyseat cutter depends on factors such as:

Commonly Used Materials

High-Speed Steels (HSS):

Cobalt High-Speed Steels:

Tungsten Carbide:

Grades: Various carbide grades with differing properties. Keyseat cutters often use tougher, less brittle grades for shock resistance.

Benefits: Exceptional hardness, wear resistance, and high-temperature performance. Ideal for cutting very hard materials and demanding applications.

Limitations: Higher cost and can be more brittle than HSS, requiring careful handling.

Baucor: Your Material and Cutting Solutions Specialist

Baucor's expertise extends to helping you choose the ideal material for your full radius keyseat cutters. We consider all factors impacting your machining operations.

Benefits of Coatings:

Coatings provide several advantages for full radius keyseat cutters:

Common Coating Options

Baucor's Coating Expertise

Baucor's team can advise on the best coating solution for your full radius keyseat cutters based on:

Applications of Full Radius Keyseat Cutters in Industry

Full radius keyseat cutters, also known as Woodruff keyseat cutters, find essential use in various manufacturing and machining processes where secure component locking and smooth torque transmission are required.

Key Areas of Use

Industries Where Full Radius Keyseat Cutters are Common

General Manufacturing: Diverse applications across industries where rotating components need to be securely fixed.

Full radius keyseat cutters (Woodruff key cutters) are indispensable in industries where precision, secure component coupling, and efficient machining are paramount. Here's a comprehensive look:

Automotive Manufacturing:

Aerospace Industry:

Heavy Machinery & Equipment:

Power Generation:

Oil and Gas:

Drill strings and downhole tools

Valves, pumps, and critical components in refining and distribution infrastructure.

Why Full Radius Keyseat Cutters Are Preferred

Baucor: Your Partner in Precision Machining

Baucor's expertise extends to providing full radius keyseat cutter solutions tailored to the demanding needs of various industries. We offer:

Common Machine Types

Full radius keyseat cutters can be used on a variety of machine types, offering flexibility for different production environments:

Factors in Machine Selection

The ideal machine for your full radius keyseat cutter depends on factors such as:

Baucor: Keyseat Cutters for Your Machining Setup

Our team can help match the right full radius keyseat cutters to your specific machines and applications. We consider:

As a world-leading keyseat cutter specialist, Baucor understands that achieving optimal results involves more than just a premium tool. We offer comprehensive design and engineering support, including:

Baucor: Your Partner in Optimized Keyseat Solutions

By partnering with Baucor, you gain access to:

Key Design Elements and Considerations

Design Factors Influenced by Application

Baucor: Your Keyseat Cutting Design Resource

Baucor's engineers leverage their design expertise to create full radius keyseat cutters optimized for specific applications. We consider: