BAUCOR END MILLS: THE PERFECT BLEND OF STRENGTH AND PRECISION

ENGINEERED TO EXCEL!

BAUCOR END MILLS: THE PERFECT BLEND OF STRENGTH AND PRECISION

ENGINEERED TO EXCEL!

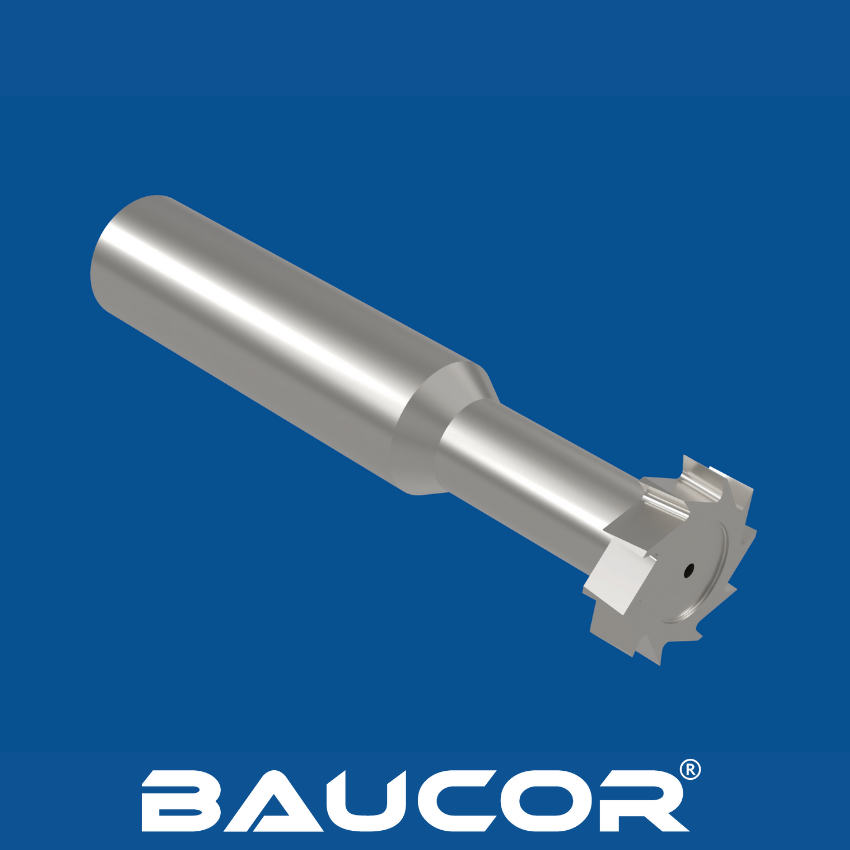

What is a Staggered Tooth Keyseat Cutter?

Keyseat cutters are essential tools in manufacturing, used to create precise grooves (keyseats) within shafts or bores. These grooves lock components like gears or pulleys in place, ensuring synchronized rotation. Staggered tooth keyseat cutters offer several advantages over traditional straight-fluted cutters.

How Does a Staggered Tooth Keyseat Cutter Work?

Keyseat cutters, with their specialized staggered tooth design, are precision tools that play a vital role in industrial machining. Here's a breakdown of how they're manufactured:

Key Manufacturing Steps

Baucor's Expertise in Keyseat Cutter Manufacturing

Baucor, a leading manufacturer of industrial cutting tools, possesses the capabilities and expertise to produce exceptional staggered tooth keyseat cutters.

Standard Size Ranges

Baucor likely offers a comprehensive range of staggered tooth keyseat cutters to suit various industrial applications. Here's how to clearly categorize the sizes:

Metric:

Imperial:

Factors Influencing Size Selection

Materials for Strength, Durability, and Precision

Selecting the right material for your staggered tooth keyseat cutter is crucial for optimal machining outcomes. Here's a detailed look at the options:

1. High-Speed Steels (HSS)

2. Cobalt High-Speed Steels

3. Tungsten Carbide

4. Powdered Metal (PM)

5. Specialty Materials

The Benefits of Coatings for Keyseat Cutters

Common Coating Options for Keyseat Cutters

Woodruff Key End Mills are used to create the semi-circular keyways that accommodate Woodruff keys for a secure shaft-to-hub connection.

A Tipped Off Chamfer Cutter is a cutting tool with a replaceable cutting tip designed to create beveled edges or chamfers on a workpiece, commonly used in machining and milling operations for precision edge finishing.

Keyseat cutters are essential tools in manufacturing, used to create precise grooves (keyseats) within shafts or bores. These grooves lock components like gears or pulleys in place, ensuring synchronized rotation.

A Concave Radius Milling Cutter is a specialized milling tool designed to create concave or inwardly curved profiles on a workpiece, often used for machining grooves, rounded edges, and complex shapes.

Applications of Staggered Tooth Keyseat Cutters in Industry

Staggered tooth keyseat cutters are essential tools in various manufacturing and machining operations where precision and secure component locking are required.

Key Areas of Use

Industries Where Staggered Tooth Keyseat Cutters are Common

Staggered tooth keyseat cutters are indispensable in industries where precision, secure component coupling, and efficient machining are paramount. Here's a detailed look:

Automotive:

Aerospace:

Heavy Machinery & Equipment:

Power Generation:

Oil and Gas:

Drill strings, downhole tools, and complex pipeline assemblies.

Valves, pumps, and other critical components in production and distribution infrastructure.

The Advantages of Staggered Tooth Cutters

Industries favor staggered tooth keyseat cutters because they offer:

Baucor: Your Partner in Precision Machining

Baucor's expertise extends to providing keyseat cutter solutions tailored to the demanding needs of various industries. We offer:

Common Machine Types

Staggered tooth keyseat cutters are versatile tools that can be used on various machine types:

Factors in Machine Selection

Baucor: Keyseat Cutters for Your Machining Setup

Baucor's team can help match the right staggered tooth keyseat cutters to your specific machines and applications. We consider:

End Mill Neck Relief is the reduced diameter section behind the cutting edge of an end mill, designed to provide clearance and reduce tool deflection during deep cutting operations.

T-Slot End Mills are specifically designed to cut T-shaped slots, commonly used for securing components in machinery.

Tapered Ball Nose End Mill is a specialized cutting tool with a tapered body and rounded tip, ideal for 3D contouring and smooth surface finishing in CNC milling and engraving applications.

Pointed chamfer cutters are a type of end mill used specifically for creating chamfers – angled cuts that transition between two surfaces.

Design and Engineering Support Beyond the Tool

Baucor, a world-leading keyseat cutter specialist, understands that optimizing keyseat machining involves more than just a premium cutting tool. We offer comprehensive design and engineering support, including:

Baucor: Your Partner in Optimized Keyseat Solutions

By partnering with Baucor, you gain access to:

BAUCOR offers custom manufacturing and engineering solutions tailored to your specific needs, across various industries.

BAUCOR's engineers can review your design and provide feedback to improve manufacturability, cost effectiveness, and efficiency.

Key Design Elements and Considerations

Shear Angles: Alternating right-hand and left-hand shear angles for smoother cutting and chip evacuation.

Rake Angles: Optimized for the intended workpiece materials. Positive rake angles are common for softer materials, while more neutral or negative rakes may be used for harder ones.

Relief Angles: Provide clearance and prevent rubbing.

Design Factors Influenced by Application

Baucor: Your Keyseat Cutting Design Resource

Baucor's engineers leverage their design expertise to create staggered tooth keyseat cutters optimized for specific applications. We consider: