Standard vs. Custom CNC Tools: Which Is Right for Your Operation?

Standard vs. Custom CNC Tools: Which Is Right for Your Operation ?

Let’s take a look at the best tools for you! For example, those diligently creating perfect parts using your CNC machines. There’s a big choice in machining: should you keep using tried and trusted standard tools or hire different and better-suited Custom CNC tools? It’s a lot like the difference between buying off-the-shelf and having something made for you.

We’ll explore this discussion today to help you see if contract or in-house solutions are right for your business and how CNC tools are the key to getting the results you need.

The Allure of Standard CNC Tools: The Reliable Workhorse

Let's start with the familiar. Standard CNC tools are, well, standard for a reason. They are mass-produced, readily available, and designed to perform a wide range of common machining operations. Think of them as the dependable generalists in your toolbox.

Pros of Standard CNC Tools:

-

Availability: You can often find them on the shelf at your local supplier or with quick delivery online. No waiting around!

-

Cost-Effective (Per Unit): Due to mass production, the individual unit cost of a standard tool is typically lower.

-

Proven Performance: Their capabilities are well-documented, and there’s a wealth of application data and recommendations available.

-

Familiarity: Most machinists are trained to use standard tools, reducing the learning curve.

-

Easy Replacement: If one breaks, getting a replacement is usually straightforward.

Cons of Standard CNC Tools:

-

Compromise: They are designed for general applications, meaning they might not be optimized for your specific material, geometry, or machine parameters. This often translates to suboptimal performance.

-

Reduced Efficiency: Using a standard tool for a specialized task can lead to longer cycle times, more passes, and slower feed rates.

-

Subpar Finishes: Without optimized geometry, you might struggle to achieve the desired surface finish, potentially requiring secondary operations.

-

Limited Capabilities: They simply can't tackle highly complex features, tight tolerances in difficult materials, or multi-function tasks.

The Precision Powerhouse: Embracing Custom CNC Tools

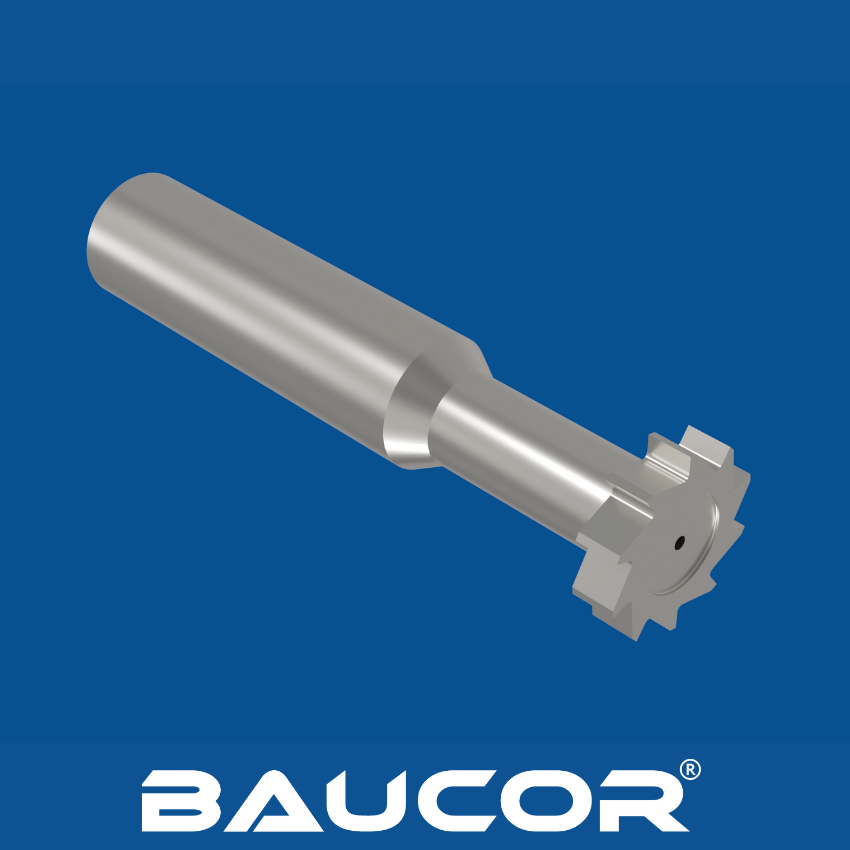

Let’s now look at what Custom CNC tools have to offer. They are built and developed to fit the particular application, material or part shape being used. They are made specifically to excel in exactly the work they do.

Why Opt for Custom CNC Tool Manufacturing?

The decision to invest in Custom CNC tools often stems from a need to overcome limitations imposed by standard tooling. This is where specialized CNC Tool Manufacturing houses become your crucial partners.

Pros of Custom CNC Tools:

-

Optimized Performance: This is the biggest win. Custom tools are designed precisely for your material, machine, and part, leading to maximum material removal rates, faster cycle times, and superior surface finishes.

-

Complex Geometries: They can be designed to machine intricate features, undercuts, or multi-angle cuts in a single pass, simplifying programming and reducing setups.

-

Extended Tool Life: Optimized geometry and specialized coatings mean custom tools often last significantly longer in demanding applications, reducing tool changes and downtime.

-

Reduced Tooling Inventory: A single custom tool might replace multiple standard tools, simplifying your inventory and potentially reducing overall tooling costs in the long run.

-

Consolidated Operations: A multi-feature custom tool can combine several machining steps into one, leading to massive time savings and increased accuracy by eliminating re-fixturing errors.

-

Problem Solving: They are often the go-to solution for overcoming persistent machining challenges like chip evacuation issues, chatter, or achieving impossible tolerances with standard tools.

Cons of Custom CNC Tools:

-

Higher Upfront Cost: Designing and manufacturing a custom tool is more expensive per unit than a standard tool.

-

Longer Lead Time: There's a design and production phase involved, meaning you can't get them instantly.

-

Specificity: If your production run of the specific part ends, the custom tool might become obsolete.

-

Reliance on Manufacturer: You're dependent on the expertise and quality of your CNC Tool Manufacturing partner.

When to Make the Leap: Strategic Considerations

So, when is the investment in Custom CNC tools truly justified? Here are some scenarios where they typically shine:

1. High Production Volumes: For long production runs, even small gains in cycle time or tool life translate into massive cost savings over the lifetime of the project. The higher upfront cost of custom tools is quickly recouped.

2. Difficult-to-Machine Materials: Working with superalloys (Inconel, Titanium), hardened steels, or composites often pushes standard tools to their limits. Custom geometries and coatings are essential for efficient machining and tool longevity.

3. Complex Part Geometries & Tight Tolerances: When your part has intricate features, deep cavities, or extremely tight tolerances that standard tools struggle to achieve, custom solutions can be the only way to meet specifications without multiple setups or secondary operations.

4. Bottleneck Operations: If a specific machining step is consistently slowing down your production line, a custom tool can be designed to eliminate the bottleneck and improve overall throughput.

5. Cost Reduction in the Long Run: While the individual tool cost is higher, the savings in cycle time, tool changes, scrap reduction, and improved part quality can lead to a significantly lower cost per part.

The Art and Science of CNC Tool Manufacturing

Whether you choose standard or custom, the quality of CNC Tool Manufacturing is paramount. For custom tools, it’s not just about cutting metal; it’s a highly specialized process involving:

-

Advanced CAD/CAM Design: Sophisticated software is used to design the precise geometry of the tool, simulating cutting performance before physical production.

-

Premium Substrate Materials: Choosing the right grade of carbide (or other materials) is critical for matching the tool's performance to the application.

-

Precision Grinding: State-of-the-art CNC grinding machines with sub-micron accuracy are essential for creating complex geometries and razor-sharp edges.

-

Specialized Coatings: Applying advanced PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) coatings enhances hardness, lubricity, and heat resistance, dramatically improving tool life and performance.

-

Rigorous Quality Control: Every custom tool undergoes meticulous inspection to ensure it meets the exact specifications and performance requirements.

Conclusion: A Strategic Decision for Your Operation

Deciding on standard or Custom CNC tools isn’t black and white because there are many factors to consider. Choosing between machines is a matter of what operations you have, your production amounts, the problems with materials and your only expectations.

Your standard tools help you handle everyday work with ease. Still, when fast, precise work, shorter cycle times, saving effort and dealing with complex problems matter, adopting Custom CNC tools from trusted partners gives a real advantage. A detailed examination of your applications can tell you when a CNC Tool Solution will both cover its costs and help your manufacturing reach unprecedented levels.

English

English