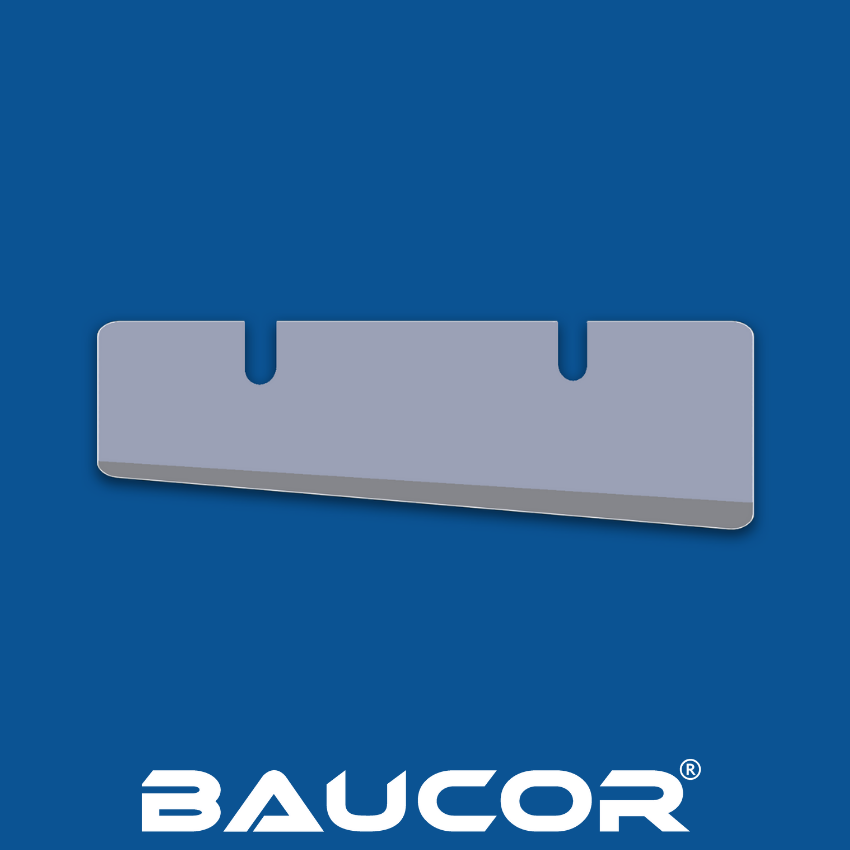

Shear knives are thin, flat-cutting tools used to cut sheet metal or other materials by applying a shearing force. They are typically made of high-grade steel and are used in various industrial applications, including press brakes, guillotine shears, and other machines that cut sheet metal or other materials by applying a shearing force.

Shear knives are typically designed to be precise and durable, and they may be coated with a hard material to improve their cutting ability and extend their lifespan. In addition to cutting sheet metal, shear knives can cut other materials, such as paper, rubber, or plastic.

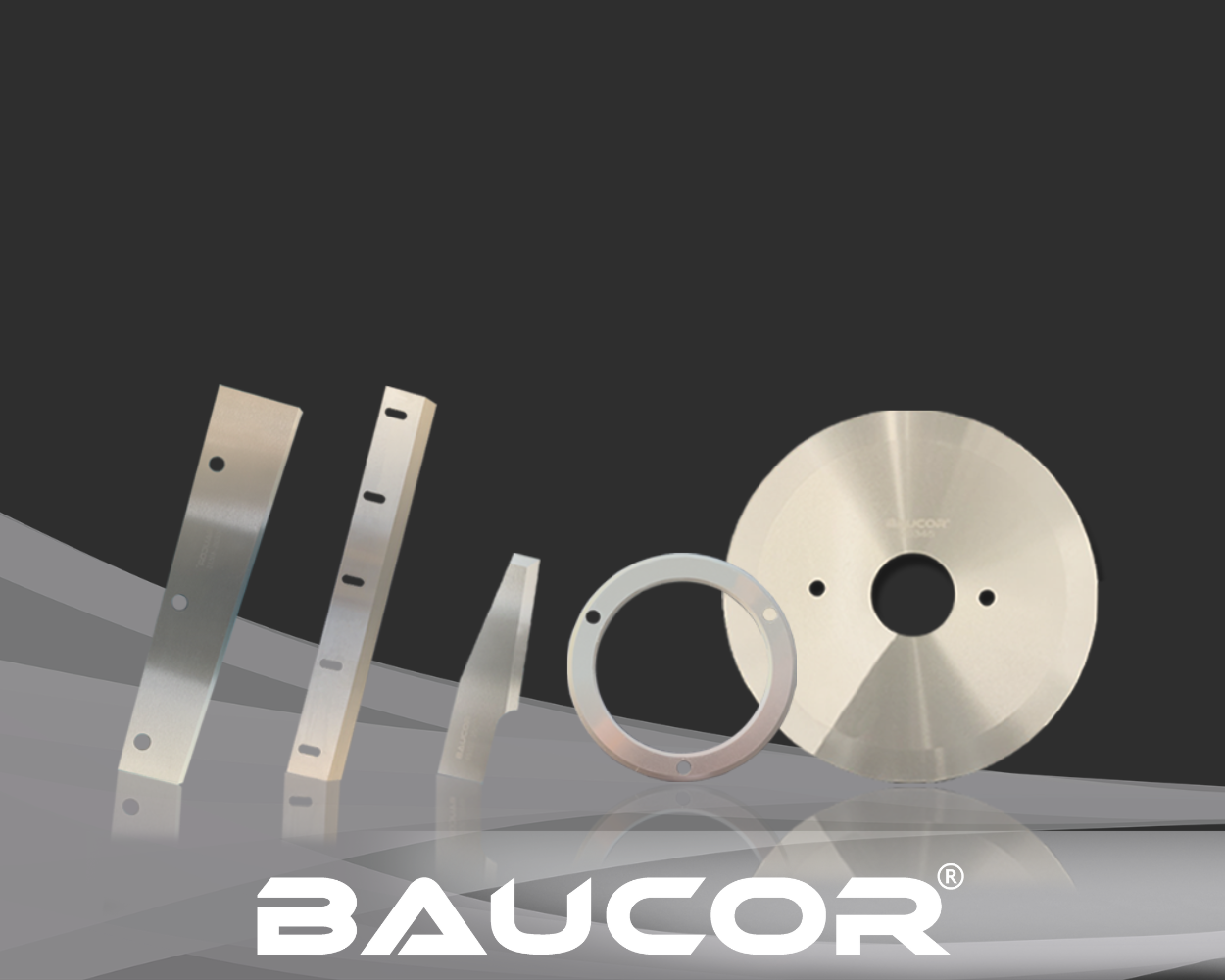

Baucor manufactures and supplies both precision standard and custom size rotary shear blades and flat shear knives for most application. Our rotary shear blades and flat shear knives are exceptionally made from quality ground hardened tool steels and stainless steel as well as carbide.

English

English