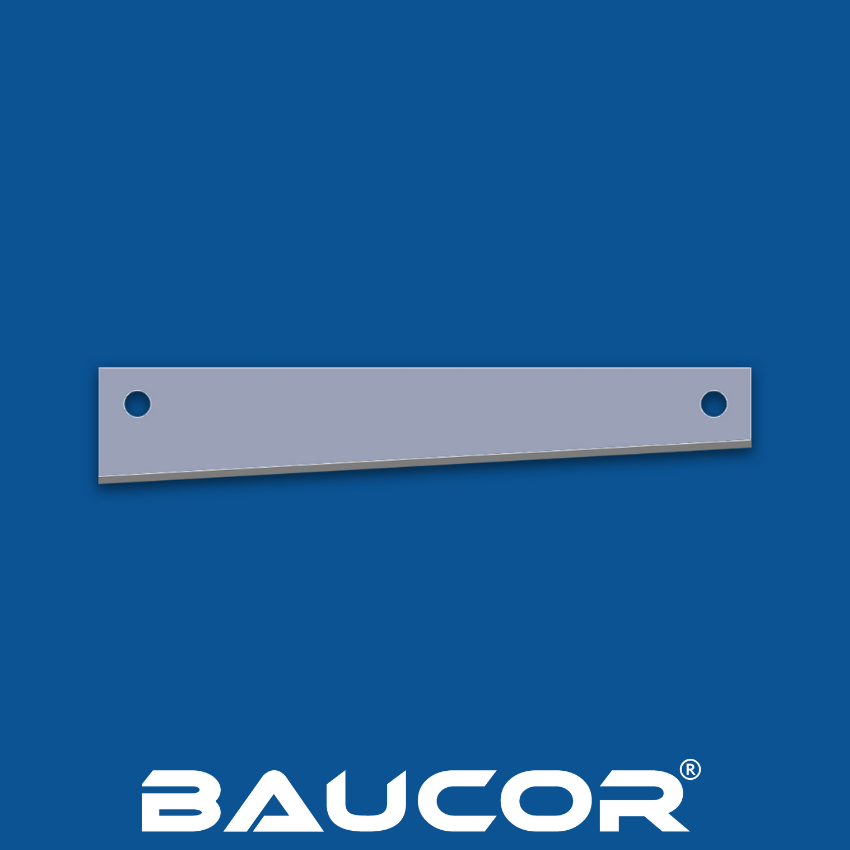

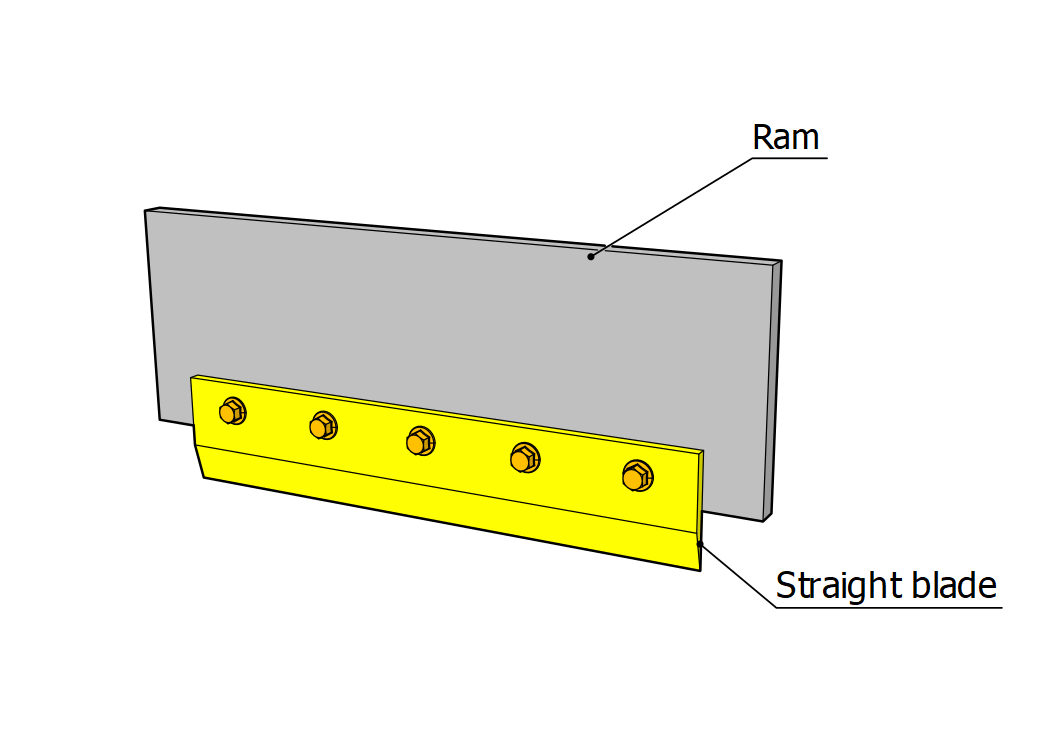

Scraper blades are tools designed to scrape or remove materials from a surface. They typically have a flat or curved blade made of metal, plastic, or another durable material and are used to remove excess or unwanted material from various surfaces.

Scraper blades are used in various applications, including construction, automotive repair, and manufacturing. They can be used to remove paint, sealant, adhesive, rust, or other materials from surfaces and to smooth or finish surfaces by removing imperfections or excess material. Scraper blades are available in various shapes and sizes to suit different applications.

Whether you need an industrial scraper knives or food scraper blades for ice cream freezers, Baucor has the experience to manufacture all shapes and kinds of industrials scraper knives and blades. Whether you need an industrial scraper knives or food scraper blades for ice cream freezers, Baucor has the experience to manufacture all shapes and kinds of industrials scraper knives and blades.

English

English