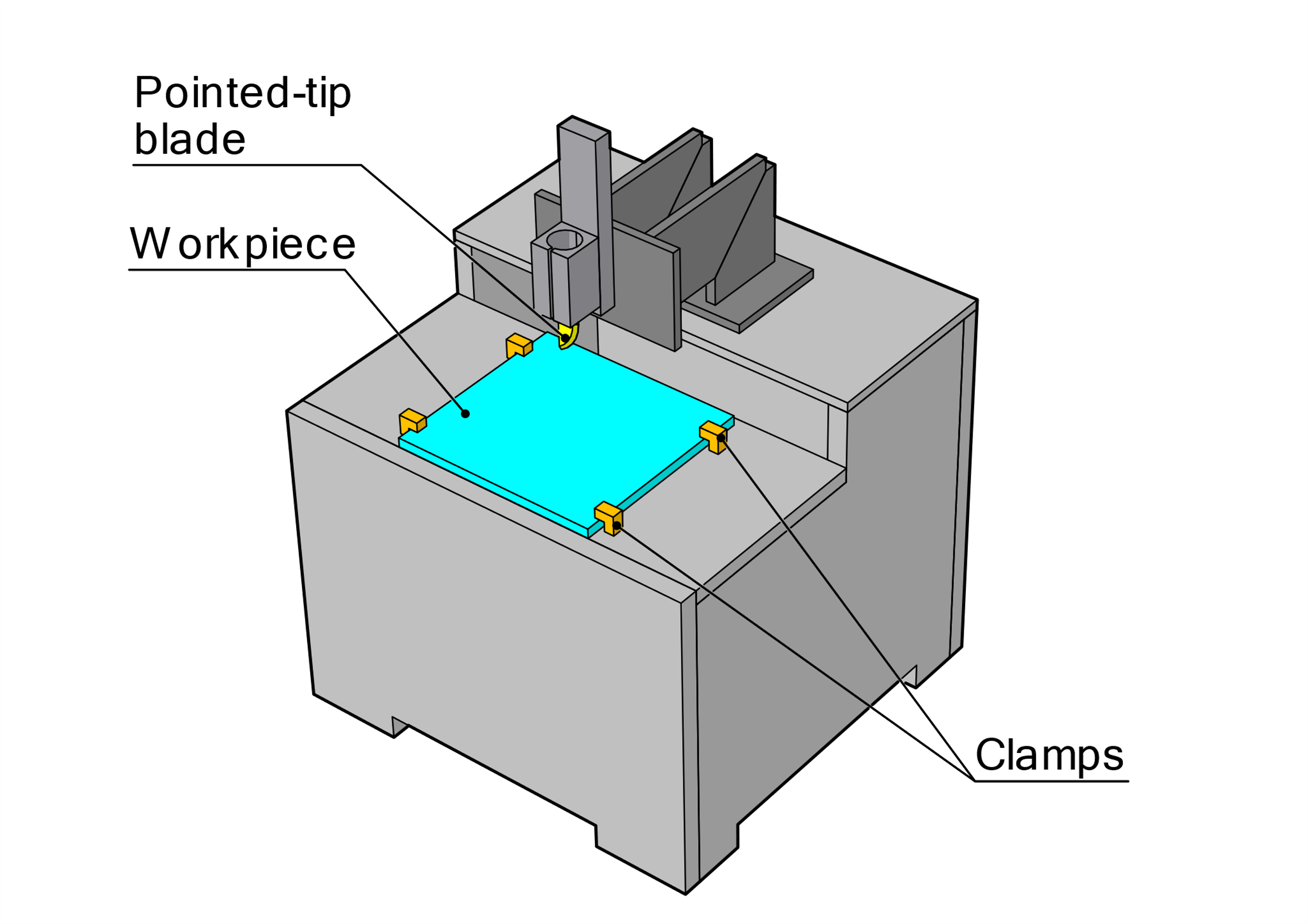

A pointed-tip blade is a type of knife with a narrow, sharp point at the end of the blade. This blade type can be used for various tasks, from piercing, puncturing, slicing, and opening packages. The blade can be made from different materials but is most commonly made from steel.

Although the pointed-tip blade is handy, it can be hazardous. The sharp point can easily cause serious injuries, and the blade can be broken if misused. It is crucial to handle this blade carefully and always use it with caution.

Baucor manufactures and supplies both standard and custom-built pointed tip knives and blades from a size of a razor blade to a large shear blade for all kinds of industrial use. Our pointed tip knives and blades are made from quality ground hardened tool steels and stainless steel as well as tungsten carbide.

English

English